Thermal Oil Heater for Flue Gas Desulfurization and Denitrification

Product Detail

Thermal oil heater is to directly heat the electric heater into the organic carrier (heat conducting oil). It uses circulating pump to force the heat conducting oil to circulate in liquid phase. The heat is transferred to one or more heat-using equipment. After unloading the heat equipment, the electric heater is returned to the heater through the circulating pump, and then the heat is absorbed and transferred. The transfer of heat equipment, so cycle after cycle, to achieve the continuous transfer of heat, so that the temperature of the heated object rises, to meet the heating process requirements.

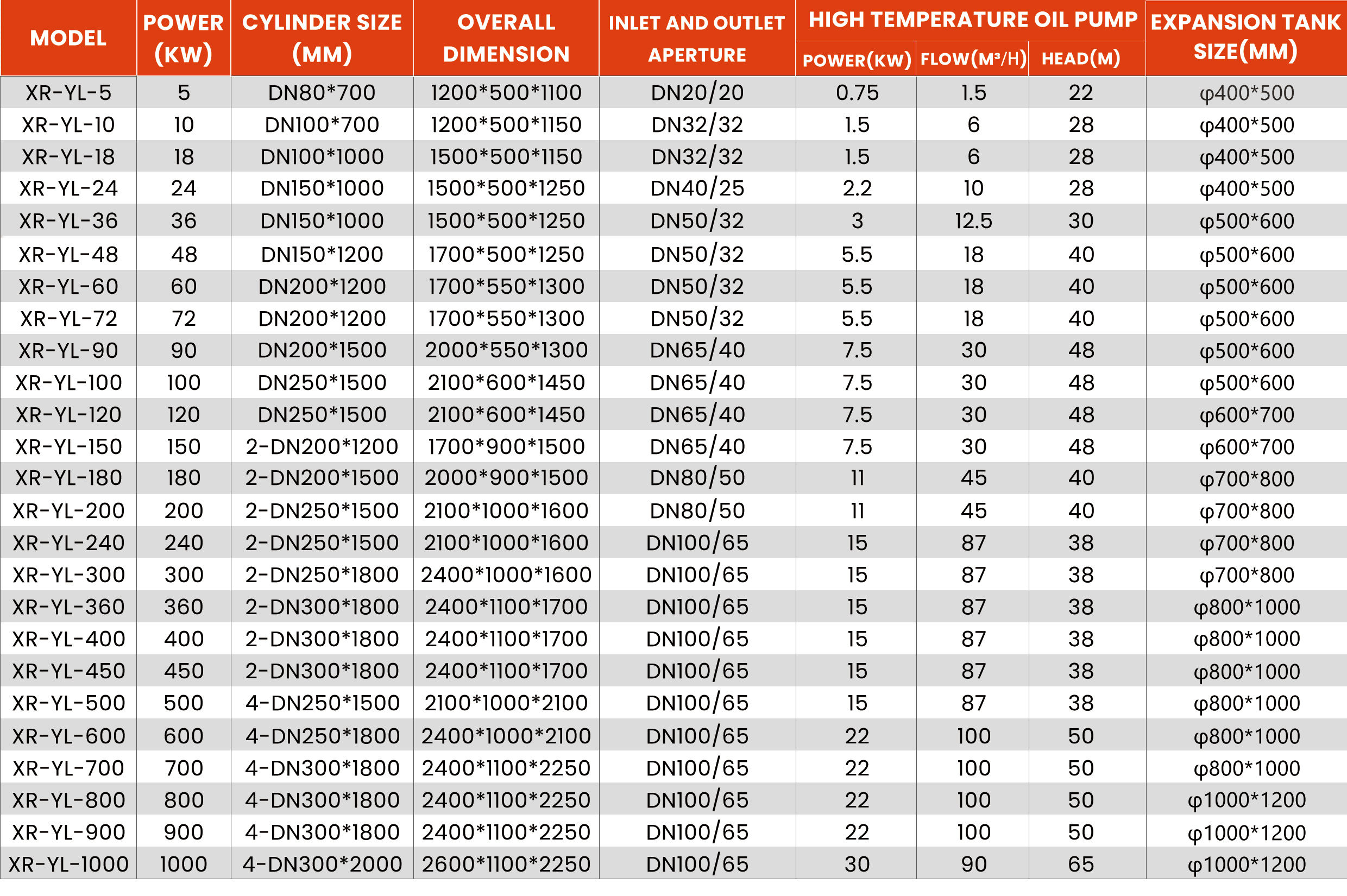

Parameter table

Features

(1) It runs at a lower pressure and get a higher operating temperature.

(2) It can get the stable heating and precise temperature.

(3) Thermal Oil Heater has complete operational control and security monitoring devices.

(4) Thermal oil furnace helps to save electricity, oil and water, and can recover investment in 3 to 6 months.

Application

Thermal oil electric heater is widely used on hot roller/hot rolling machine, calender/kneader, radiator/heat exchanger, reaction kettle/distillating machine, drying oven/drying room/drying tunnel, Laminator/ Vulcani zing machine