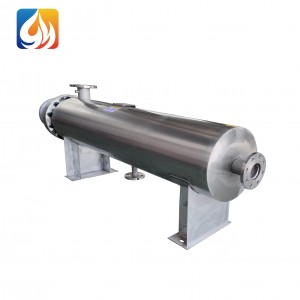

Stainless steel 304 inline water heater in pharmaceutical industry

Product Detail

An pipeline heater is composed of an immersion heater covered by an anti-corrosion metallic vessel chamber. This casing is mainly used for insulation to prevent heat loss in the circulation system. Heat loss is not only inefficient in terms of energy usage but it would also cause unnecessary operation expenses. A pump unit is used to transport the inlet fluid into the circulation system. The fluid is then circulated and reheated in a closed loop circuit around the immersion heater continuously until the desired temperature is reached. The heating medium will then flow out of the outlet nozzle at a fixed flow rate determined by the temperature control mechanism. The pipeline heater is usually used in urban central heating, laboratory, chemical industy and textile industry.

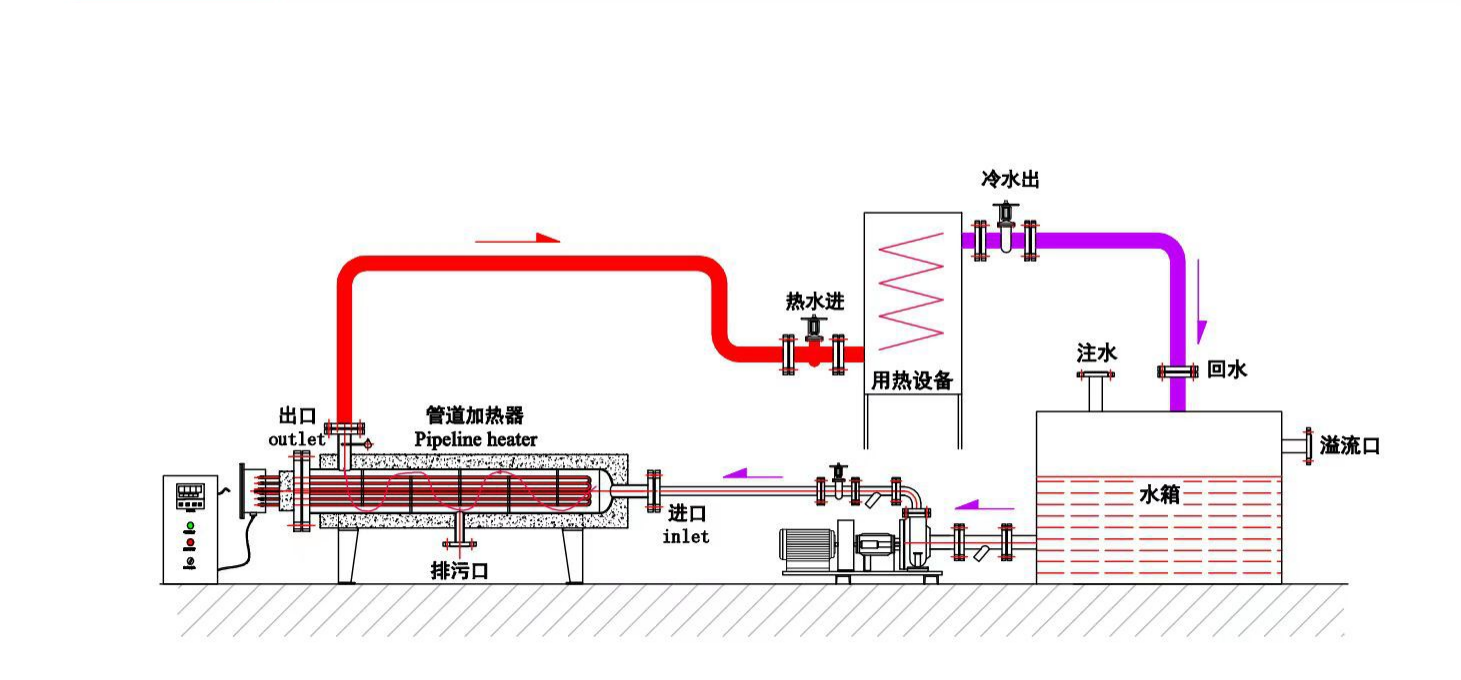

Working Diagram

Pipeline heater's working principle is: cold air (or cold liquid) enters the pipeline from the inlet, the inner cylinder of the heater is in full contact with the electric heating element under the action of the deflector, and after reaching the specified temperature under the monitoring of the outlet temperature measurement system, it flows from the outlet to the specified piping system.

Feature

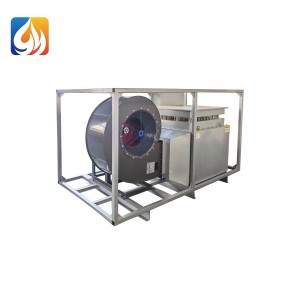

1. Pipeline heater is made of stainless steel cylinder, small volume, convenient for movement, with strong corrosion resistance, between the stainless steel liner and stainless steel shell, there is a thick insulation layer, maintain temperature and save energy.

2. High quality heating element (stainless steel electric heating tube) are made of imported materials. Its insulation, voltage resistance, moisture resistance are higher than the national standards, safe and reliable use.

3. Medium flow direction design is reasonable, heating uniform, high thermal efficiency.

4. the pipeline heater is installed with domestic well-known brand temperature controller, the user can set the temperature freely. All heaters is equipped with overheat protectors, used to control the temperature and water shortage and overtemperature protection, to avoid the damage of heating elements and system.

Structure

The pipeline heater is mainly composed of an U shaped electric flange immersion heating element, an inner cylinder, an insulation layer, an outer shell, a wiring cavity, and an electronic control system.

|

Technicial Specifications |

|||||

|

Model |

Power(KW) |

Pipeline Heater (liquid) |

Pipeline Heater (air) |

||

|

heating room size(mm) |

connection diameter (mm) |

heating room size(mm) |

connection diameter (mm) |

||

|

SD-GD-10 |

10 |

DN100*700 |

DN32 |

DN100*700 |

DN32 |

|

SD-GD-20 |

20 |

DN150*800 |

DN50 |

DN150*800 |

DN50 |

|

SD-GD-30 |

30 |

DN150*800 |

DN50 |

DN200*1000 |

DN80 |

|

SD-GD-50 |

50 |

DN150*800 |

DN50 |

DN200*1000 |

DN80 |

|

SD-GD-60 |

60 |

DN200*1000 |

DN80 |

DN250*1400 |

DN100 |

|

SD-GD-80 |

80 |

DN250*1400 |

DN100 |

DN250*1400 |

DN100 |

|

SD-GD-100 |

100 |

DN250*1400 |

DN100 |

DN250*1400 |

DN100 |

|

SD-GD-120 |

120 |

DN250*1400 |

DN100 |

DN300*1600 |

DN125 |

|

SD-GD-150 |

150 |

DN300*1600 |

DN125 |

DN300*1600 |

DN125 |

|

SD-GD-180 |

180 |

DN300*1600 |

DN125 |

DN350*1800 |

DN150 |

|

SD-GD-240 |

240 |

DN350*1800 |

DN150 |

DN350*1800 |

DN150 |

|

SD-GD-300 |

300 |

DN350*1800 |

DN150 |

DN400*2000 |

DN200 |

|

SD-GD-360 |

360 |

DN400*2000 |

DN200 |

2-DN350*1800 |

DN200 |

|

SD-GD-420 |

420 |

DN400*2000 |

DN200 |

2-DN350*1800 |

DN200 |

|

SD-GD-480 |

480 |

DN400*2000 |

DN200 |

2-DN350*1800 |

DN200 |

|

SD-GD-600 |

600 |

2-DN350*1800 |

DN200 |

2-DN400*2000 |

DN200 |

|

SD-GD-800 |

800 |

2-DN400*2000 |

DN200 |

4-DN350*1800 |

DN200 |

|

SD-GD-1000 |

1000 |

4-DN350*1800 |

DN200 |

4-DN400*2000 |

DN200 |

Application

Pipeline heaters are widely used in automobiles, textiles, printing and dyeing, dyes, papermaking, bicycles, refrigerators, washing machines, chemical fiber, ceramics, electrostatic spraying, grain, food, pharmaceuticals, chemicals, tobacco and other industries to achieve the purpose of ultra-fast drying of the pipeline heater. Pipeline heaters are designed and engineered for versatility and are capable of meeting most applications and site requirements.

Buying Guide

The key questions before ordering a pipeline heater are:

Our Company

Jiangsu Yanyan Industries Co.,Ltd is a comprehensive high-tech enterprise focusing on design, production and sales for electric heating equipments and heating elements, which is located on Yancheng City, Jiangsu Province, China. For a long time, the company is specialized on supplying the superior technical solution, our products have been export to many countries, we have clients in more than 30 countries all over the world.

The company has always attached great importance to the early research and development of products and quality control during the production process. We has a group of R&D, production and quality control teams with rich experience in electrothermal machinery manufacturing.

We warmly welcome domestic and foreign manufacturers and friends to come to visit, guide and have business negotiation!