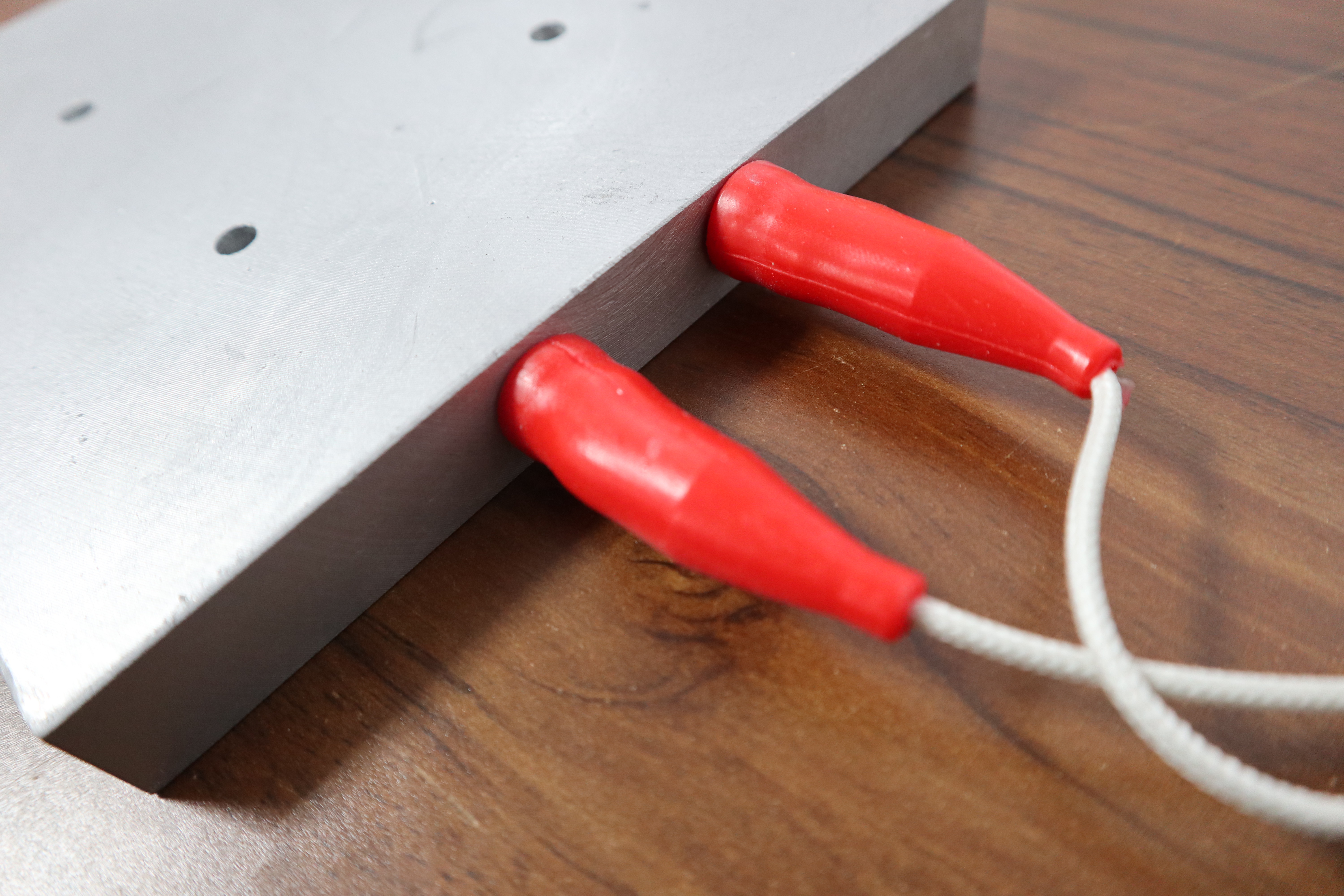

Cast aluminum heating plate refers to a heater that uses an electric heating tube as the heating element, is bent into a mold, and is made of high-quality aluminum alloy material as the shell, and is manufactured by die-casting or centrifugal casting. Mainly used to heat materials, air or liquids. Its working principle is mainly to energize and heat the electric heating tube inside the cast aluminum heating plate, transfer the heat to the entire heating plate, and then transfer the heat to the material, air or liquid that needs to be heated through various methods.

Specifically, cast aluminum heating plates can be used in the heating systems of various industrial kilns, drying equipment, reactors and other equipment to achieve uniform heating of materials, air or liquids, improve heating efficiency, shorten heating time, and save energy. In the fields of plastics, rubber, building materials, chemicals, etc., cast aluminum heating plates have broad application prospects.

In addition, cast aluminum heating plates also have excellent corrosion resistance and high temperature resistance, can operate stably under harsh environmental conditions, and meet various complex process requirements. At the same time, the manufacturing process of cast aluminum heating plates is simple and easy to maintain and maintain, which can save costs and improve production efficiency for enterprises.

In general, the cast aluminum heating plate is an efficient, energy-saving and environmentally friendly heating equipment that can meet various industrial heating needs.

Post time: Feb-22-2024