Electrical performance requirements

Power accuracy: The rated power of the electric heating tube should be consistent with the design power of the air duct heater, and the deviation should generally be controlled within ± 5% to ensure that it can provide accurate and stable heat to the air in the air duct and meet the heating needs of the system.

Insulation performance: The insulation resistance should be high enough, generally not less than 50MΩ at room temperature and not less than 1MΩ at working temperature, to ensure electrical safety during use and prevent leakage accidents.

Voltage resistance performance: able to withstand certain voltage tests, such as maintaining a voltage of 1500V or higher for 1 minute without breakdown, flashover, or other phenomena, ensuring reliable operation within the normal operating voltage fluctuation range.

Mechanical performance requirements

High temperature resistance: The air temperature inside the air duct is high, and the surface of the electric heating tube should be able to withstand high temperatures, such as working for a long time at 300 ℃ or even higher, without deformation, melting or other problems. High temperature resistant metal materials such as stainless steel 310S are usually used to make the heating wire and shell.

Corrosion resistance: If the air in the air duct contains corrosive gases or has high humidity, the electric heating tube should have good corrosion resistance, such as using corrosion-resistant coatings or alloy materials, to prevent the service life from being reduced or performance from being affected by corrosion.

Mechanical strength: It has sufficient mechanical strength to withstand external impacts during installation and transportation, as well as the impact of airflow in the air duct, and is not easily broken or damaged.

Thermal performance requirements

Heating efficiency: Electric heating tubes should have high heating efficiency, which can quickly convert electrical energy into thermal energy, causing the air temperature in the air duct to rise rapidly. Generally, the thermal efficiency is required to be above 90%.

Thermal uniformity: The heat distribution on the entire surface of the electric heating tube and the cross-section of the air duct should be as uniform as possible to avoid local overheating or overcooling, in order to ensure the consistency of the temperature of the heated air. Generally, the temperature uniformity is required to be within ± 5 ℃.

Thermal response speed: able to quickly respond to temperature control signals, and can quickly increase or decrease the temperature when the system is started or adjusted, meeting the system's timely requirements for temperature regulation.

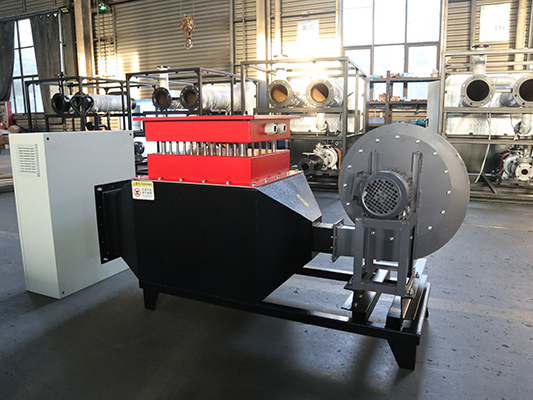

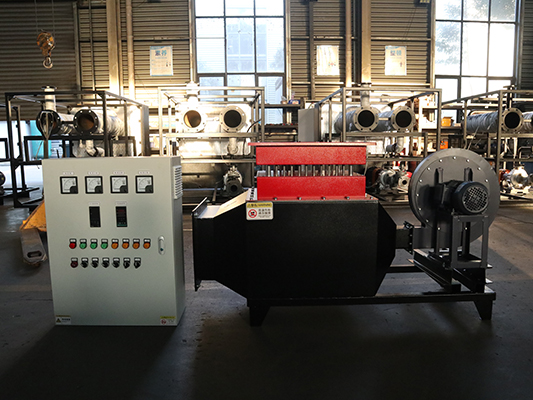

Structural design requirements

Shape and size: According to the shape, size, and installation position of the air duct, the electric heating tube needs to be designed in a suitable shape and size, such as U-shaped, W-shaped, spiral shaped, etc., to fully utilize the air duct space, ensure good contact with the air inside the air duct, and achieve efficient heat transfer.

Installation method: The installation method of the electric heating tube should be easy to disassemble and maintain, while ensuring a firm installation and good insulation and sealing with the air duct wall to prevent heat loss and air leakage.

Heat dissipation structure: Reasonably design the heat dissipation structure, such as adding heat dissipation fins, to improve the heat dissipation effect, reduce the surface temperature of the electric heating tube, extend the service life, and improve the heating efficiency.

Safety performance requirements

Overheating protection: Equipped with overheating protection devices or functions, it can automatically cut off the power supply when the temperature of the electric heating tube exceeds the set safe temperature, preventing safety accidents such as fires.

Grounding protection: A reliable grounding device is installed to ensure that in the event of an electrical fault, the current can quickly enter the ground, ensuring the safety of personnel and equipment.

Material safety: The materials used for electric heating tubes should comply with relevant safety standards, not release harmful gases or substances, and ensure that they do not pollute the air or pose a threat to human health during the heating process.

Service life requirements

Long term stability: Under normal working conditions, electric heating tubes should have a long service life, generally requiring a continuous working time of not less than 10000 hours to reduce maintenance costs and improve system reliability.

Anti aging performance: in the process of long-term use, the performance of the electric heating tube should be stable and not prone to aging, performance degradation and other problems. For example, the heating wire will not become brittle and broken due to long-term heating, and the insulation material will not lose its insulation performance due to aging.

Post time: Feb-19-2025