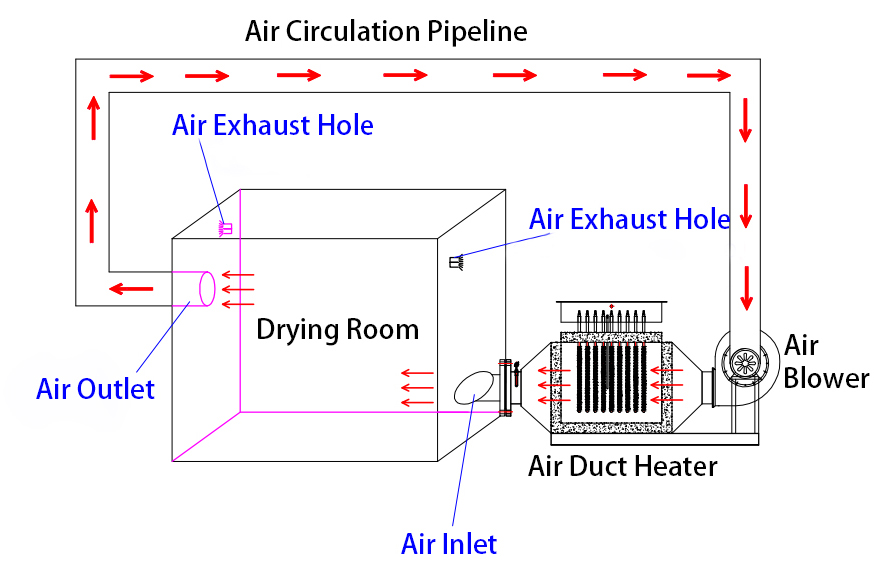

The heating principle of the air duct paint drying room heater is as follows:

1. Heating element generates heat:

Resistance wire heating: The core heating element of the air duct paint drying room heater is a stainless steel electric heating tube, which is uniformly equipped with electric heating wires (i.e. resistance wires) inside the seamless steel pipe. When current passes through a resistance wire, due to the presence of resistance, the current does work and generates a large amount of heat in the resistance wire. This is the heat source for the entire heating process, effectively converting electrical energy into thermal energy.

The function of magnesium oxide powder is to fill the gap between the resistance wire and the steel pipe with magnesium oxide powder that has good thermal conductivity and insulation properties. Magnesium oxide powder can serve as insulation to prevent short circuits between resistance wires and steel pipes, ensuring the safe operation of the heater; On the other hand, it can efficiently transfer the heat generated by the resistance wire to the surface of the steel pipe, improving the efficiency of heat transfer.

2. Heat transfer to gas:

Thermal conduction: When the surface of a stainless steel electric heating tube receives heat, the heat is first transferred to the gas in contact with the heating tube through thermal conduction. After obtaining heat, gas molecules increase their kinetic energy and temperature.

Gas flow and heat exchange: Usually, a fan is equipped in the drying room to create a flow of gas in the air duct. The flowing gas continuously passes through the surface of the heating tube and undergoes continuous heat exchange with the heating tube, thereby continuously heating up the gas. Moreover, the inner cavity of the air duct heater is generally equipped with multiple baffles (guide plates), which can guide the flow of gas, prolong the residence time of gas in the heater cavity, allow the gas to fully absorb heat, make the gas heating more uniform, and improve the efficiency of heat exchange.

Heat transfer and drying: The heated gas is transported to various positions in the drying room through the air duct under the action of the fan, and heats and dries the paint and other objects that need to be dried. The hot gas transfers heat to the paint, causing the solvents in the paint to quickly evaporate, thereby achieving the drying and curing of the paint.

If you have a air duct paint drying room heater related needs, welcome to contact us.

Post time: Nov-08-2024