Customized Pipeline Heaters: Tailoring Heat for Industrial Needs

In the realm of industrial processes, the management of fluid temperatures is crucial for the efficiency and safety of operations. Customized pipeline heaters play a pivotal role in this aspect, offering a solution that is tailored to meet specific requirements. Here are the key considerations for designing and implementing a customized pipeline heating system:

1. Fluid Type and Properties: The nature of the fluid being heated is fundamental. Different fluids have varying thermal conductivities, viscosities, and chemical properties, which affect the choice of heating elements and materials.

2. Temperature Range: Defining the required temperature range is essential. The system must be capable of maintaining the fluid within the desired temperature limits, from the lowest to the highest required temperature.

3. Flow Rate: The rate at which the fluid moves through the pipeline influences the heat transfer efficiency. A higher flow rate may necessitate a more powerful heating system to maintain the temperature.

4. Pressure and Volume: The pressure and volume of the fluid within the pipeline are critical. These factors determine the structural integrity and safety requirements of the heating system.

5. Heat Loss: An assessment of potential heat loss is necessary to ensure that the heating system compensates for any losses due to ambient conditions or the material of the pipeline.

6. Safety and Regulatory Compliance: Industrial heating systems must adhere to safety standards and regulatory requirements. This includes the use of certified components and adherence to guidelines for operation and maintenance.

7. Energy Efficiency: Customizing a pipeline heater to be energy efficient not only reduces operational costs but also aligns with environmental sustainability goals.

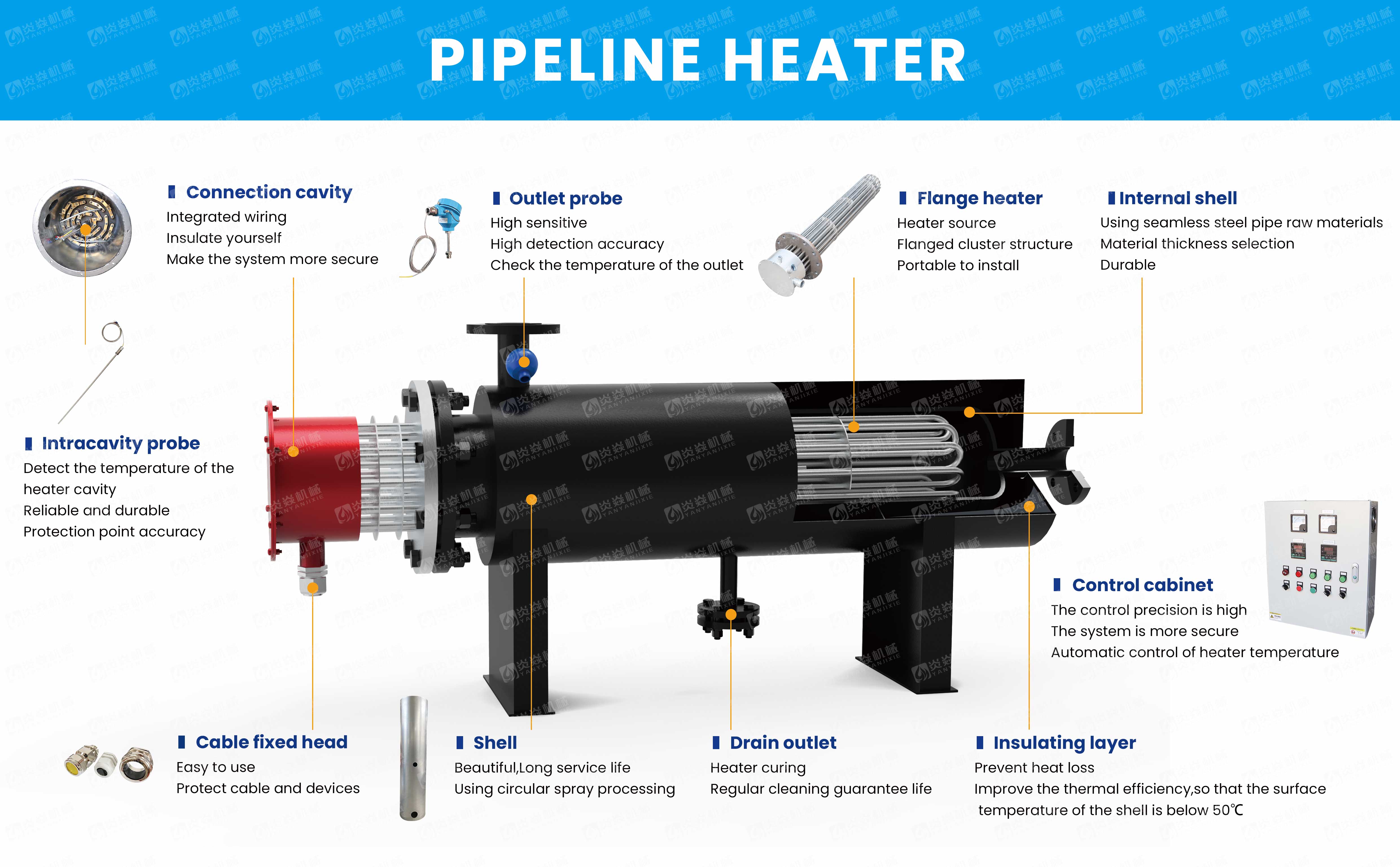

8. Control Systems: Advanced control systems are often integrated into customized heaters to monitor and adjust the temperature automatically, ensuring precise control and reducing the risk of human error.

9. Materials and Construction: The choice of materials for the heating elements and the construction of the heater itself must resist corrosion, withstand high temperatures, and be compatible with the fluid being heated.

10. Maintenance and Serviceability: A well-designed system should be easy to maintain and service, with accessible components and clear guidelines for regular checks and part replacements.

Customized pipeline heaters are not a one-size-fits-all solution; they are engineered to fit the unique demands of each industrial application. By considering these requirements, industries can ensure that their heating systems are reliable, efficient, and safe.

If you have a pipeline heater related needs, welcome to contact us.

Post time: Jul-19-2024