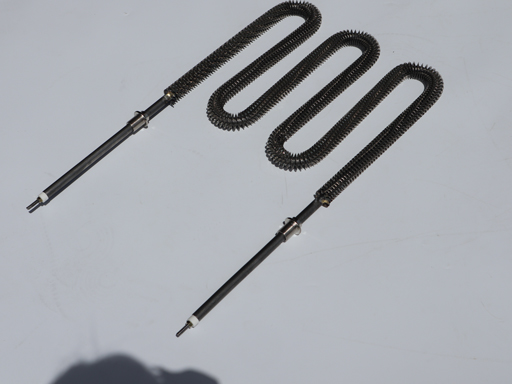

Fin heating tube is a common electric heating device. The following is an introduction to its composition, characteristics, and applications:

Product composition

Heating element: usually composed of a resistance wire wound on an insulating material, it is the core component that generates heat. Resistance wires are generally made of high resistivity alloy materials, such as nickel chromium alloys, to ensure effective conversion of electrical energy into thermal energy when energized.

Fins: Fins are an important component of finned heating tubes, usually made of metal materials such as copper, aluminum, etc. The function of fins is to increase the heat dissipation area of the heating tube asnd improve the heat transfer efficiency.

Insulation layer: The insulation layer is wrapped around the heating element to prevent short circuits between the heating element and the housing, and also plays a certain insulation role to reduce heat loss. The insulation layer is generally made of materials with high temperature resistance and good insulation performance, such as ceramics, mica, etc.

Shell: The shell is a protective component of the finned heating tube, usually made of metal materials such as stainless steel, carbon steel, etc. The function of the shell is to protect the internal heating elements and insulation layer, while also facilitating the installation and fixation of the heating tube.

Product Features

Large heat dissipation area: Due to the presence of fins, the heat dissipation area of the heating tube is greatly increased, which can quickly transfer heat to the surrounding medium and improve heating efficiency.

High thermal efficiency: The heating element of the finned heating tube is tightly integrated with the fins, allowing heat to be quickly transferred to the fins and then dissipated to the surrounding environment through the fins, reducing heat loss and improving thermal efficiency.

Compact structure: The finned heating tube has a relatively compact structure, occupies less space, and is easy to install and arrange. In some situations where space requirements are high, such as small equipment, laboratories, etc., it has great advantages.

Long service life: The finned heating tube adopts high-quality materials and advanced manufacturing processes, which make the heating tube have high temperature resistance and corrosion resistance, and can operate stably for a long time in harsh working environments, with a long service life.

High safety: Finned heating tubes usually adopt a double insulation structure, which can effectively prevent electric shock accidents from occurring. At the same time, the heating tube also has an overheat protection device. When the temperature of the heating tube exceeds the set value, the power will be automatically cut off to ensure safe use.

Product Application

Industrial heating: Fin heating tubes are widely used in various processes such as heating, insulation, and drying in the chemical, petroleum, metallurgical, and mechanical industries. For example, in chemical production, it is used to heat equipment such as reaction vessels and distillation towers; In oil extraction, it is used to heat crude oil pipelines and prevent crude oil from solidifying.

Air conditioning and heating: In air conditioning systems, finned heating tubes can be used as auxiliary heating devices to increase indoor temperature in cold weather. In some small heating equipment, such as electric heaters, warm air blowers, etc., finned heating tubes are also widely used, which can quickly and effectively increase indoor temperature.

Electronic devices: In electronic devices, finned heating tubes are commonly used to heat components that require temperature control, such as lithography equipment in semiconductor chip manufacturing processes and aging testing equipment for electronic components.

Food processing: In the food processing industry, finned heating tubes can be used for processes such as baking, drying, and sterilization of food. For example, in bakeries, biscuit factories, etc., it is used to bake bread, biscuits, and other foods; In food drying equipment, it is used to remove moisture from food and extend its shelf life.

If you want to know more about our product, please contact us!

Post time: Apr-22-2025