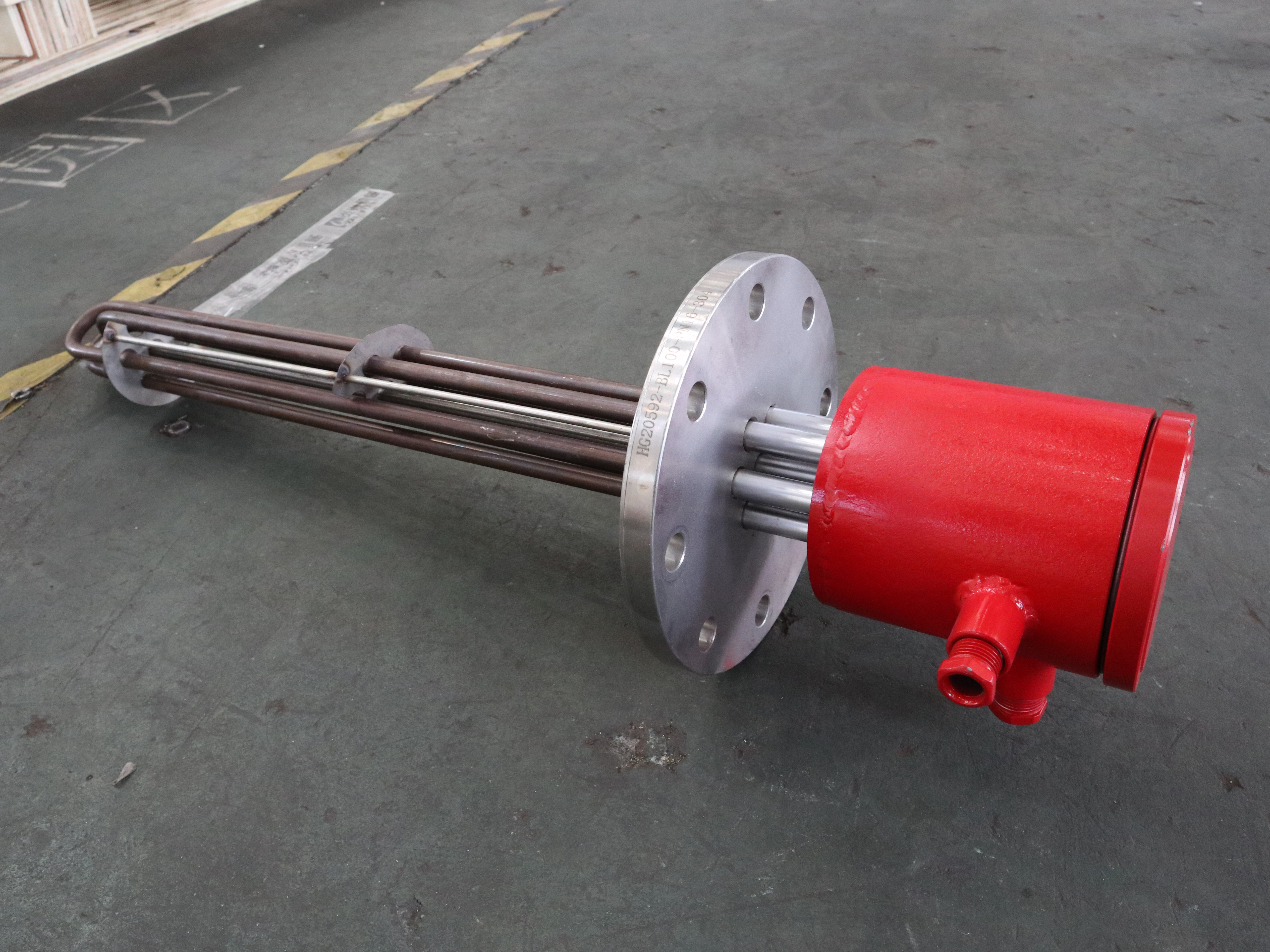

The application of flange heating pipes in industrial water tank heating is very extensive, and the following are some key points:

1、Working principle:

The flange heating tube converts electrical energy into thermal energy and directly heats the liquid in the water tank. Its core component is the electric heating element, usually made of high resistance materials. When current passes through an electric heating element, electrical energy is converted into thermal energy, thereby heating the surrounding liquid.

2、Product features:

Small size and high heating power;

The heating system can be fully automated, including controlling the electric heating system through a DCS system;

The heating temperature can generally reach 700 ℃;

Can heat various media in various occasions, such as explosion-proof situations, etc;

Long service life, with multiple protection systems, reliable.

3、Application scope:

A flange type liquid heater is a centralized heating system consisting of multiple heating tubes welded onto a flange. Mainly used for heating in open and closed solution tanks and circulation systems. Suitable for heating liquids in circulating oil, water tanks, electric boilers, medical equipment, chemical machinery, pipeline heating, reaction vessels, pressure vessels, tanks, steam heating, and solution tanks.

4、Installation method:

The flange heating tube adopts a female flange docking installation, which can be installed horizontally or vertically.

5、Specification and size selection:

• Material of pipes and flanges: stainless steel, iron;

• Cover material: Electrical grade rubberwood junction box, metal explosion-proof cover;

• Surface treatment: Blackening or greening (optional);

• Pipe process: welded pipe, seamless pipe;

• Temperature control: rotary thermostat, temperature control cabinet.

6、Precautions for use:

Wiring method: After wiring, ensure that the screws are tightened to prevent damage;

Installation method: It is necessary to ensure correct installation to avoid damage.

Post time: Nov-30-2024