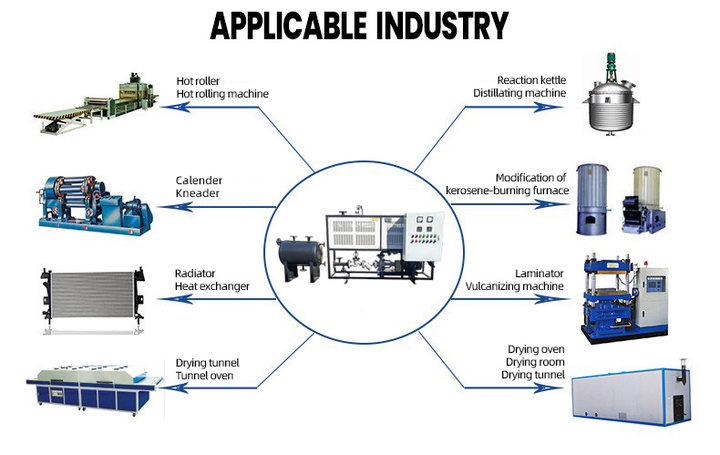

Electric thermal oil heater is a kind of special industrial furnace with high efficiency and energy saving, which is widely used in chemical industry, petrochemical industry, rubber and plastics, paint and pigment, medicine, machinery manufacturing, plastic processing, textile, grease processing and other industries. The following is an overview of the application of electric thermal oil furnace in industry:

1. Chemical industry: Electric thermal oil heater can be used for raw material heating in refining, synthesis, chlor-alkali and other production processes, providing high temperature resistant, stable and pollution-free heating environment.

2. Rubber and plastic industry: In the process of rubber production and plastic heating molding, plastic surface coating curing, electric thermal oil heater provides high temperature, high precision heating, to meet the requirements of pollution-free.

3. Paint and pigment industry: electric heating thermal oil furnace is used to heat and stabilize different raw materials to ensure product quality and stability.

4. Pharmaceutical industry: In pharmaceutical production, electric thermal oil heater can adjust different temperatures to meet the diversified needs of pharmaceutical raw material heating.

5. Machinery manufacturing industry: In the mold, bearing, forging and other industries, electric thermal oil heater is used for heat treatment to provide stable temperature control.

6. Plastic processing industry: electric thermal oil heater provides stable temperature control for plastic melting, molding, ticking and pressing molding.

7. Textile industry: In the textile process, electric thermal oil heater is used for fiber dyeing, degreasing, adsorption and other high temperature treatment processes to improve efficiency and quality.

8. Oil processing industry: electric thermal oil heater is used for vegetable oil refining and processing, animal and plant fat separation, etc., to provide a high temperature environment and improve production efficiency.

The working principle of the electric thermal oil heater is to convert electrical energy into heat energy through the electric heating element, use the heat transfer oil as the heat transfer medium, and carry out a mandatory circulation through the circulation pump to achieve continuous heat transfer. This kind of equipment has the advantages of energy saving, low operating cost, less equipment investment, safety, environmental protection and so on. During operation, the electric thermal oil heater can achieve precise temperature control, ensure that the process requirements are met, and improve production efficiency and product quality.

Post time: Jul-30-2024