Industrial Electric Hot Air Duct Heater

Product Detail

Air Duct Heater is mainly used for heating the air in the air duct. The common thing in the structure is that the steel plate is used to support the electric heating tube to reduce the vibration of the electric heating tube, and it is installed in the junction box. There is an over-temperature control device. In addition to the over-temperature protection in terms of control, an intermodal device is also installed between the fan and the heater to ensure that the electric heater must be started after the fan is started, and a differential pressure device must be added before and after the heater to prevent the fan failure, the gas pressure heated by the channel heater should generally not exceed 0.3Kg/cm2. If you need to exceed the above pressure, please use a circulating electric heater.

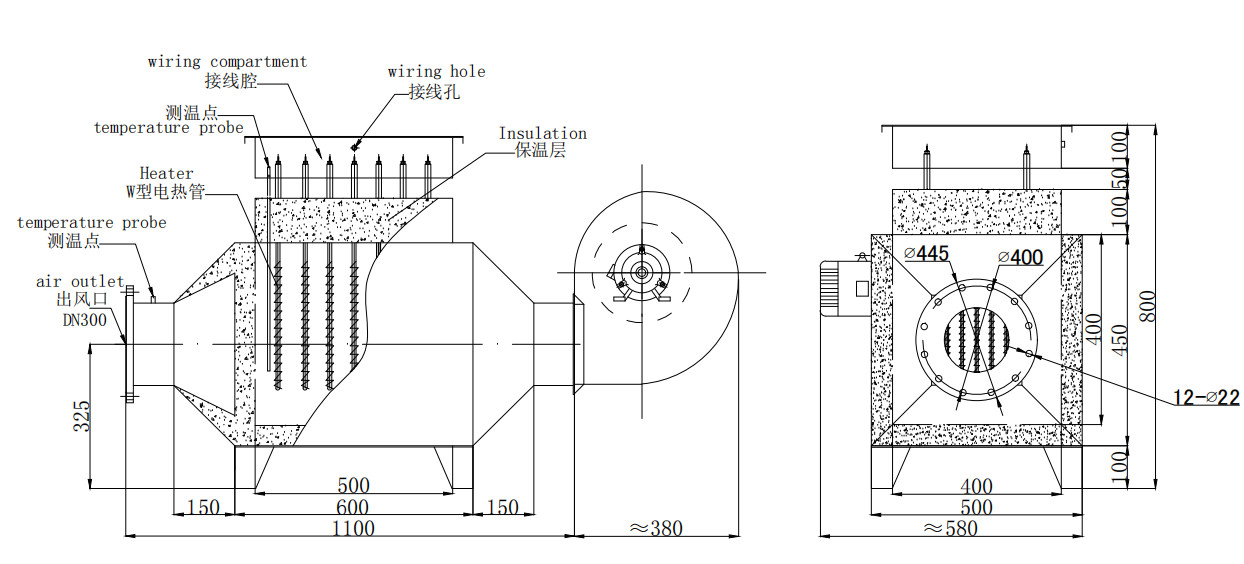

Product Structure

| Technical specifications | ||||

| Model | Power(KW) | Size of Heating Romm(L* W* H, mm) | Outlet Diameter | Power of Blower |

| SOLID-FD-10 | 10 | 300*300*300 | DN100 | 0.37KW |

| SOLID-FD-20 | 20 | 500*300*400 | DN200 | |

| SOLID-FD-30 | 30 | 400*400*400 | DN300 | 0.75KW |

| SOLID-FD-40 | 40 | 500*400*400 | DN300 | |

| SOLID-FD-50 | 50 | 600*400*400 | DN350 | 1.1KW |

| SOLID-FD-60 | 60 | 700*400*400 | DN350 | 1.5KW |

| SOLID-FD-80 | 80 | 700*500*500 | DN350 | 2.2KW |

| SOLID-FD-100 | 100 | 900*400*500 | DN350 | 3KW-2 |

| SOLID-FD-120 | 120 | 1000*400*500 | DN350 | 5.5KW-2 |

| SOLID-FD-150 | 150 | 700*750*500 | DN400 | |

| SOLID-FD-180 | 180 | 800*750*500 | DN400 | 7.5KW-2 |

| SOLID-FD-200 | 200 | 800*750*600 | DN450 | |

| SOLID-FD-250 | 250 | 1000*750*600 | DN500 | 15KW |

| SOLID-FD-300 | 300 | 1200*750*600 | DN500 | |

| SOLID-FD-350 | 350 | 1000*800*900 | DN500 | 15KW-2 |

| SOLID-FD-420 | 420 | 1200*800*900 | DN500 | |

| SOLID-FD-480 | 480 | 1400*800*900 | DN500 | |

| SOLID-FD-600 | 600 | 1600*1000*1000 | DN600 | 18.5KW-2 |

| SOLID-FD-800 | 800 | 1800*1000*1000 | DN600 | |

| SOLID-FD-1000 | 1000 | 2000*1000*1000 | DN600 | 30KW-2 |

Main Features

1) During heating, air max temperature can reach 500 degree Celsius or higher temperature, but the surface temperature of the sheath is just around 50 degree Celsius

2) Heat efficient is more than 95%

3) Temperature raise rate : 10 degree Celsius per second during working

4) The heating elements is made of high temperature alloy with good mechanical character

5) Usage time: standard more than 10 years

6) Clean air, small volume

7) Made as client design (OEM)

8) After reached the max temperate, the working wattage can reduce to half

9) The electric heating pipe is made of corrugated stainless steel strip, which increases the heat dissipation area and greatly improves the heat exchange efficiency.

10) Reasonable design of heater, small wind resistance, uniform heating, no high or low temperature dead angle.

11) Double protection, good safety performance. Temperature controllers and fuses are installed on the heater, which can be used to control the temperature of the air in the air duct and work without wind, so as to ensure that there is no mistake.