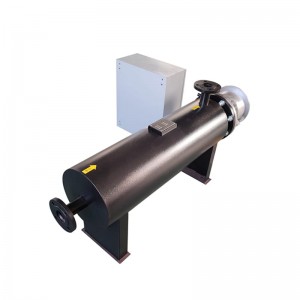

Industrial Compressed Air Heater

Product Detail

Pipeline heater is a kind of energy-saving equipment that pre-heats the material. It is installed before the material equipment to directly heat the material, so that it can circulate and heat in high temperature, and finally achieve the purpose of saving energy.

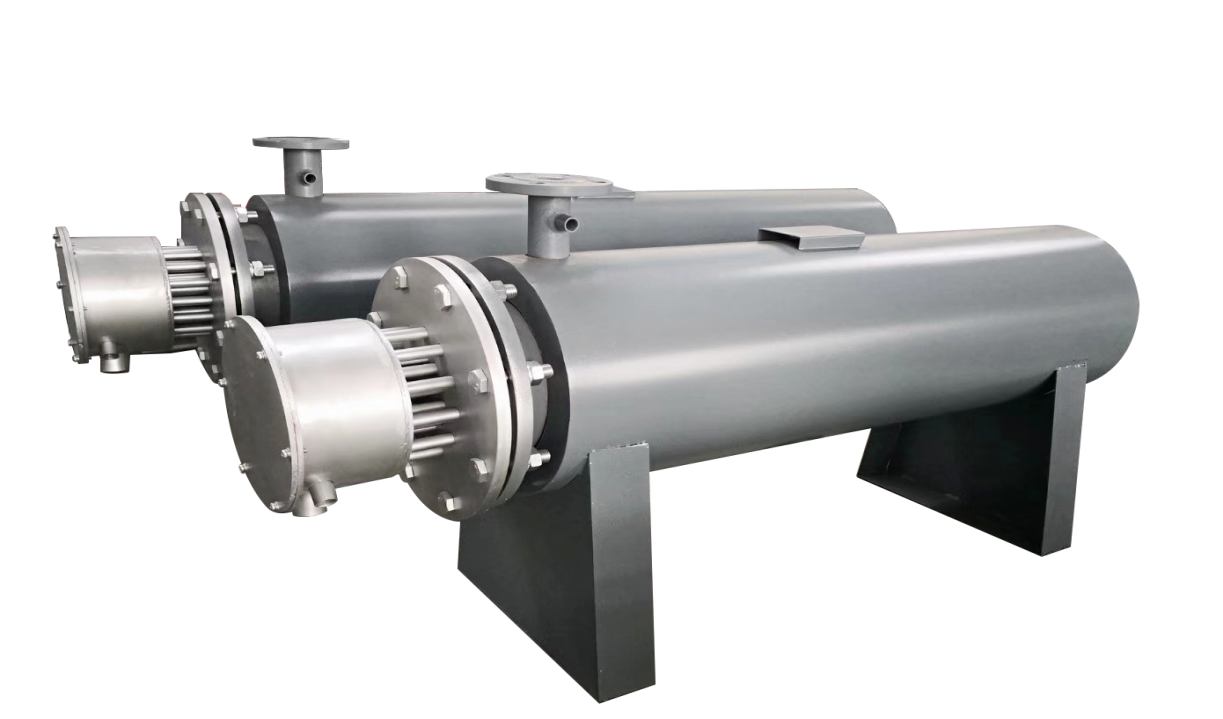

The pipeline air heater is mainly composed of an U shaped electric heating tube, an inner tube, an insulation layer, an outer shell, a wiring cavity, and an electronic control system. Its working principle is: cold air enters the pipeline from the inlet, the inner cylinder of the heater is in full contact with the electric rod under the action of the deflector, and after reaching the specified temperature under the monitoring of the outlet temperature measurement system, it flows from the outlet to the specified piping system.

| Material | Carbon steel/ SS304/ Titanium |

| Rated Voltage | ≤660V |

| Rated Power | 5-1000KW |

| Processing Temperature | 0~800 degree celsius |

| Design pressure | 0.7Mpa |

| Heating Medium | compressed air |

| Heating Element | Stainless steel immersion heater |

Feature

1. Heat efficient is more than 95%

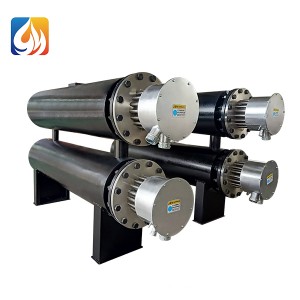

2. Vertical type pipeline heater covers a small area but has a height requirement. The horizontal type covers a large area but has no height requirement.

3. The materials of pipeline heater are: carbon steel, stainless steel SUS304, stainless steel SUS316L, stainless steel 310S, etc. Choose suitable materials according to different heating process requirements.

4. Pipeline heaters are heated by flanged electric tubes and equipped with professionally designed deflectors to ensure that the electric heating tube generates heat evenly and the heating medium fully absorbs heat.

5. For high temperature requirements (the temperature of the air outlet is greater than 600 degrees), use a high temperature resistant stainless steel 310S electric radiation heating tube for heating, and the temperature of the air outlet can reach 800 ℃.