High pressure gas line heater

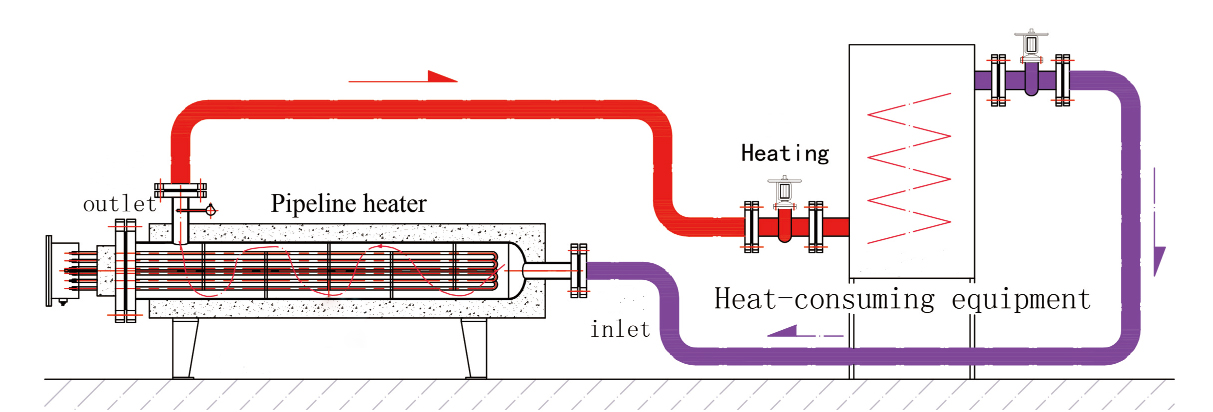

Working principle

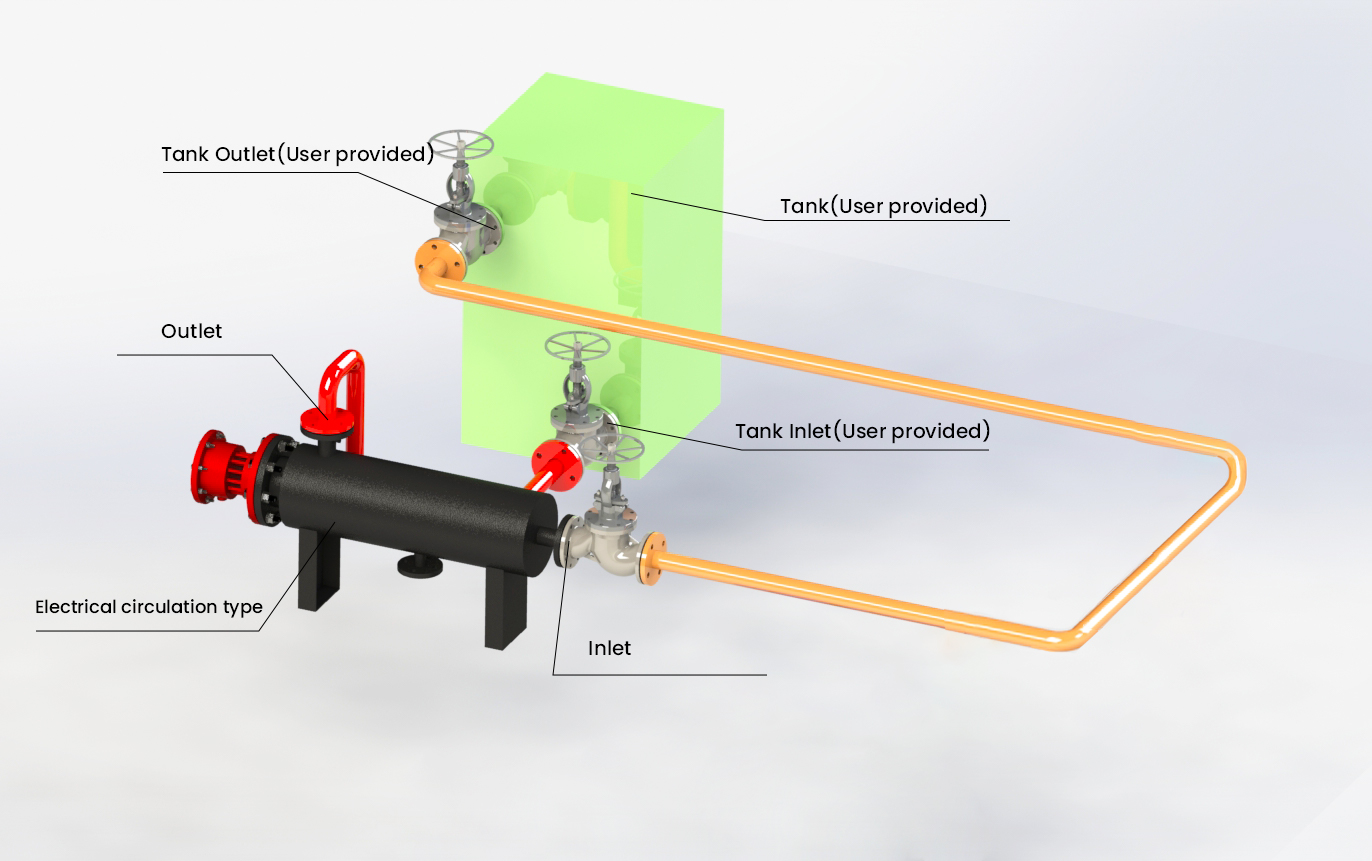

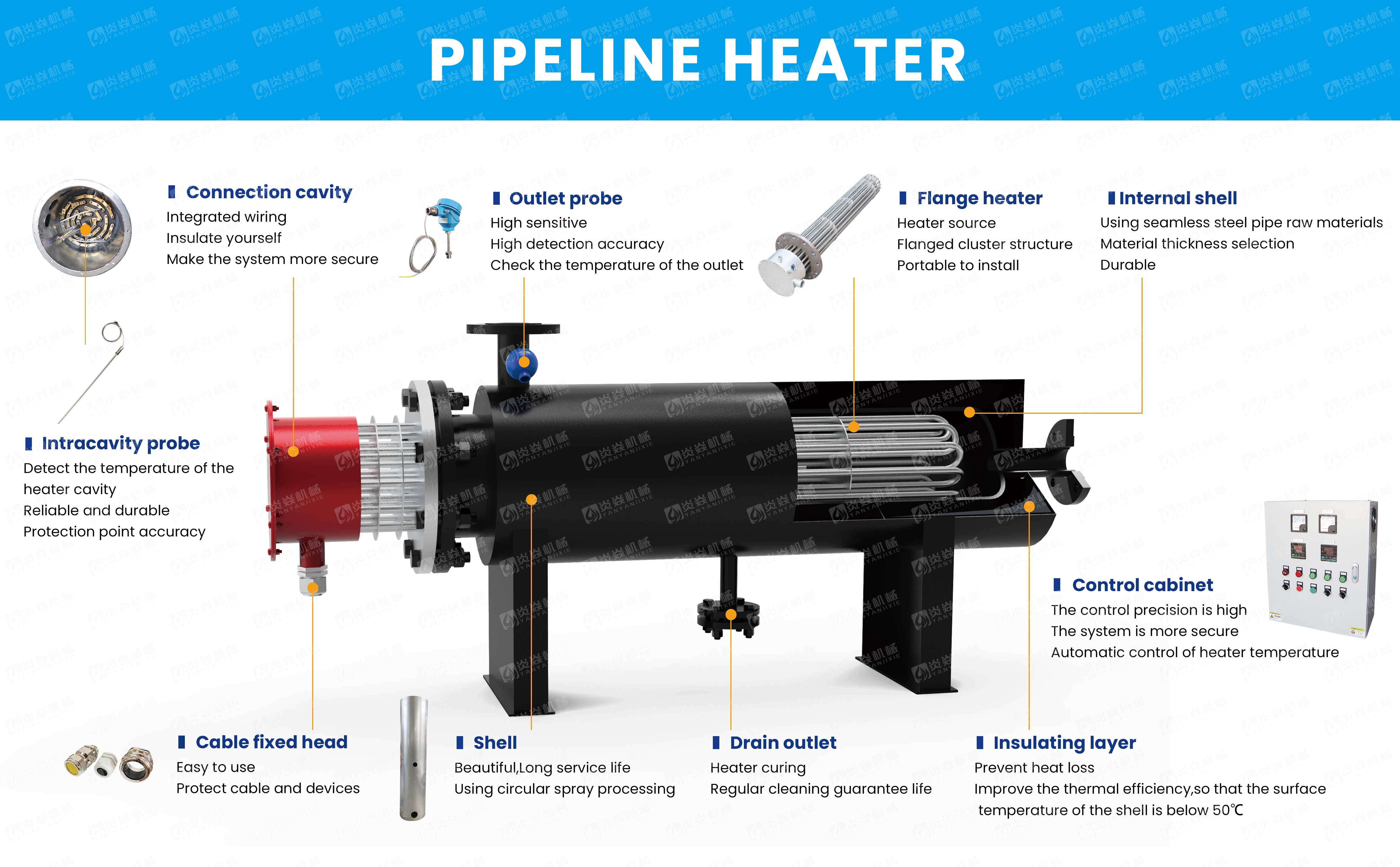

The high pressure gas line heater is composed of two parts: body and control system.Electric heating element generates heat: The electric heating element in the heater is the core part of generating heat. When an electric current passes through these elements, they generate a lot of heat.

Forced convection heating: When nitrogen or other medium passes through the heater, the pump is used to force convection, so that the medium flows and passes through the heating element. In this way, the medium, as a heat carrier, can effectively absorb heat and transfer it to the system that needs to be heated.

Temperature control: The heater is equipped with a control system including temperature sensor and PID controller. These components work together to automatically adjust the output power of the heater according to the outlet temperature, ensuring that the medium temperature is stable at the set value.

Overheating protection: In order to prevent overheating damage to the heating element, the heater is also equipped with overheating protection devices. As soon as overheating is detected, the device immediately cuts off the power supply, protecting the heating element and the system.

Product details display

Product advantage

1, the medium can be heated to a very high temperature, up to 850 ° C, the shell temperature is only about 50 ° C;

2, high efficiency: up to 0.9 or more;

3, the heating and cooling rate is fast, up to 10℃/S, the adjustment process is fast and stable. There will be no temperature lead and lag phenomenon of the controlled medium, which will cause the control temperature drift, suitable for automatic control;

4, good mechanical properties: because its heating body is special alloy material, so under the impact of high pressure air flow, it is better than any heating body mechanical properties and strength, which requires a long time continuous air heating system and accessories test is more advantageous;

5. When it does not violate the use process, the life can be as long as several decades, which is durable;

6, clean air, small size;

7, the pipeline heater can be designed according to the needs of users, multiple types of air electric heaters.

Working condition application overview

When the current passes through the heating wire inside the heater, the heating wire heats up and transfers the heat through the heat exchange to the air (gaseous medium) flowing through the heater.

In electric heating high-pressure pipe heating systems, a blower is usually included, which is responsible for blowing air into the heater. When the air flows through the heating element of the heater, it exchanges heat with the heating element, thereby increasing the air temperature. A thermocouple is installed at the outlet of the heater to monitor the outlet air temperature in real time and feed the data back to the temperature controller. The temperature controller automatically adjusts the operating state of the heater according to the set temperature to ensure the stability of the working temperature.

In addition, the electric heating high-pressure pipe heater is also equipped with multiple safety protection devices, such as overtemperature protection loop, burst port, and built-in anti-dry burning device, which are designed to further improve the safety and reliability of the equipment.

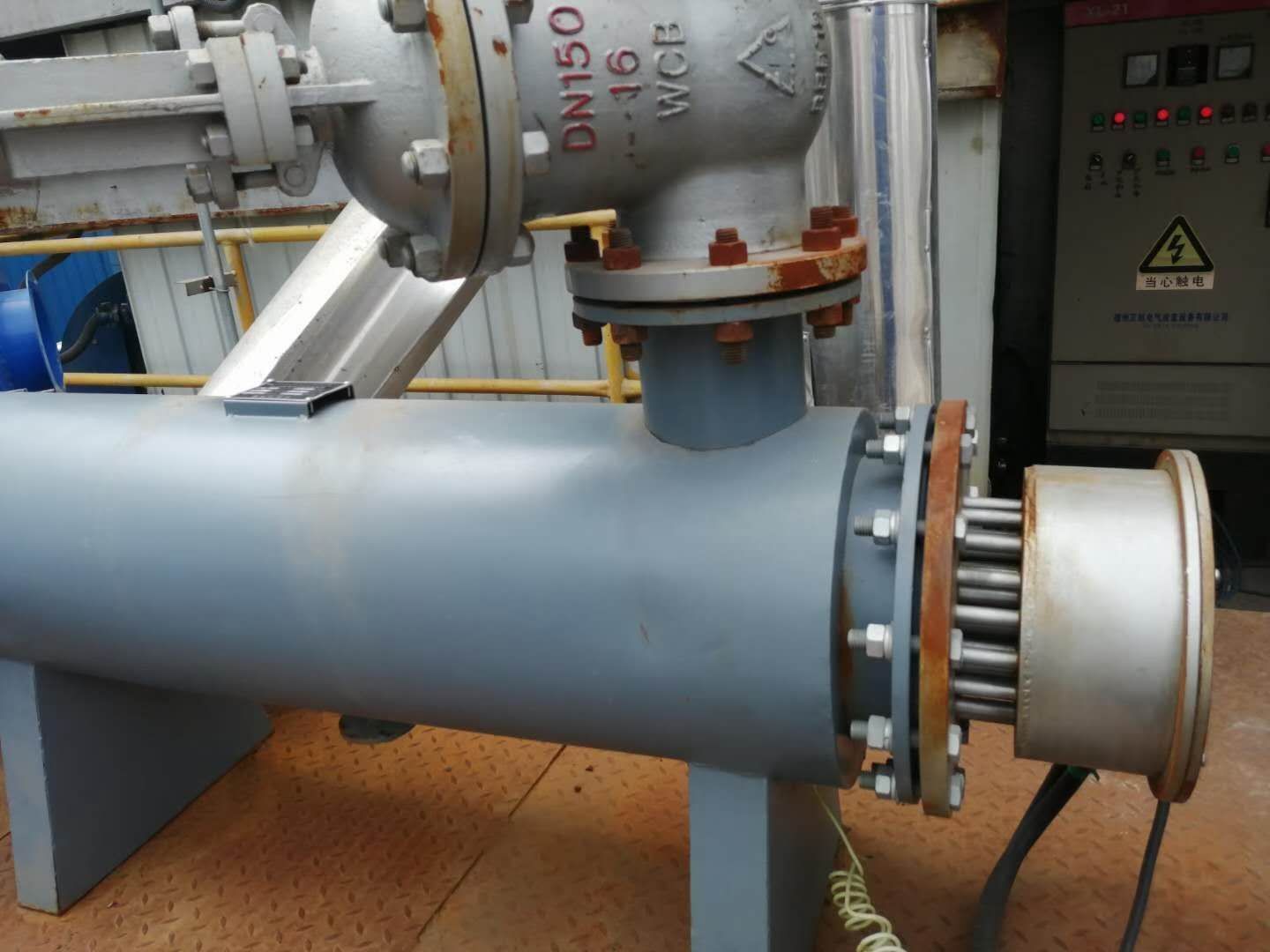

High pressure pipe heaters are manufactured with pressure vessel certificates

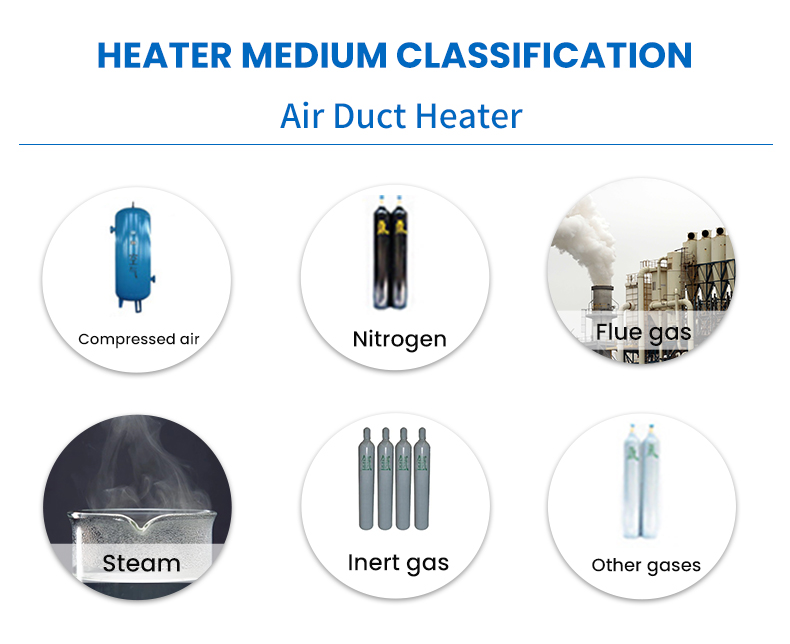

Product application

Pipeline heater is widely used in aerospace, weapons industry, chemical industry and colleges and universities and many other scientific research and production laboratory. It is especially suitable for automatic temperature control and large flow high temperature combined system and accessory test, the heating medium of the product is non-conductive, non-burning, non-explosion, no chemical corrosion, no pollution, safe and reliable, and the heating space is fast (controllable).

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services