Explosion-proof Vertical pipeline gas heater

Product Detail

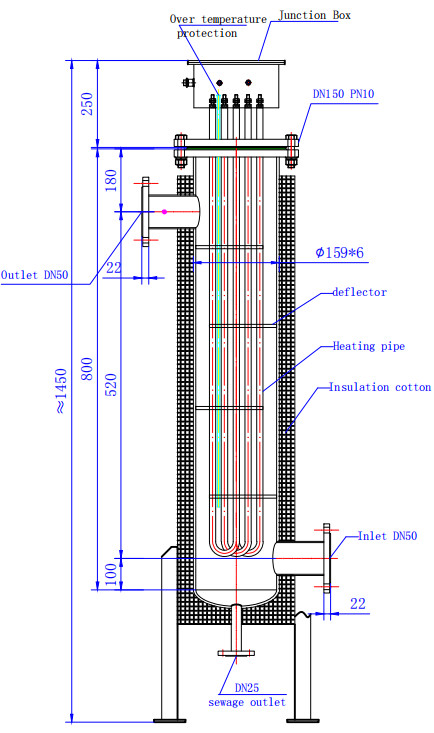

Explosion-proof Vertical gas pipeline heater is a kind of energy-saving equipment for pre-heating of the material, it is installed before the material equipment, to achieve the direct heating of the material, so that it can be heated in the high temperature cycle, and finally achieve the purpose of saving energy. It is widely used in the pre-heating of heavy oil, asphalt, clean oil and other fuel oil. The pipe heater is composed of two parts: body and control system. The heating element is made of stainless steel pipe as protection sleeve, high temperature resistance alloy wire, crystalline magnesium oxide powder, formed by compression process. The control part is composed of advanced digital circuit, integrated circuit trigger, high reverse voltage thyristor and other adjustable temperature measurement and constant temperature system to ensure the normal operation of the electric heater.

The pipeline heater is divided into two modes: one is to use the flange type tubular electric heating element inside the pipeline heater to heat the thermal oil in the reactor jacket in the pipeline heater, and transfer the heat energy in the pipeline heater to the chemical raw materials in the reactor inside the pipeline heater. Another way is to directly insert the tubular electric heating element in the pipeline heater into the reaction kettle in the pipeline heater or evenly distribute the electric heat pipe around the wall of the pipeline heater. This mode is called the internal heating of the pipe heater. The internal heating of the pipeline heater is fast and efficient.

Working principle

The Explosion-proof vertical gas pipeline heater consumes electrical energy into heat energy to heat the material that needs to be heated. At work, the low temperature enters the heater inlet under the action of pressure, and along the specific heat exchange runner inside the electric heating container, takes away the high temperature energy generated by the electric heating element in the work, so that the temperature of the heated medium rises, and the medium reaches the process requirement temperature at the outlet of the electric heater.

The control system inside the electric heater automatically adjusts the output power of the heater according to the temperature sensor signal of the outlet, so that the temperature of the outlet medium is uniform;

When the heating element exceeds the temperature, the independent thermal protection device of the heating element immediately cuts off the heating power supply to avoid the overtemperature of the heating material causing coking, deterioration, carbonization, and serious burning of the heating element, which can extend the service time of the heater.

Pipe heaters are divided into horizontal and vertical, working principle is the same.

1, the vertical pipe heater occupies a small area but the height is required, the horizontal occupies a large area but the height is not required.

2, vertical, horizontal pipe heater material: carbon steel, stainless steel SUS304, stainless steel SUS316L, stainless steel 310S and so on. Select suitable materials according to different heating process requirements.

3, the pipe heater adopts flange type electric heating pipe, and is equipped with a professional design of the baffle, to ensure that the electric heat pipe heating uniform and heating medium fully absorb heat.

4, high temperature requirements (air outlet temperature is greater than 600 degrees), the use of high-temperature stainless steel 310S electric radiation heating tube heating, air outlet temperature up to 800 degrees.

Customer use case

FAQ

1. Q: Are you factory or trading company?

A: Yes, we are factory and have 8 production lines.

2. Q: What's the shipping method?

A: International express and sea transportation, depend on customers.

3. Q: Can we use our own forwarder to transport the products?

A: Yes, sure. We can ship to them.

4. Q: Can we print our own brand?

A: Yes, of course. Will be our pleasure to be one your good OEM manufacture in China to meet your requirements.

5. Q: What's the payment method?

A: T/T, 50% deposit before production, the balance before delivery.

Also, we accept go through on alibaba, west union.

6. Q: How to place an order?

A: Please kindly send us your order by email, we will confirm the PI with you. We wish to get your email address, phone number, destination, transportation way. And product information, size, quantity, logo, etc.

Anyway, please contact us directly by email or online message.

Our Company

Yancheng Xinrong Electronic Industries Co., Ltd. is a comprehensive high-tech enterprise focusing on design, production and sales for electric heating equipments and heating elements.For example, air Duct Heater/air Pipeline Heater/liquid Pipeline Heater/thermal Oil Furnace/Heating Element/thermocouple, etc.

We has a group of R&D, production and quality control teams with rich experience in electrothermal machinery manufacturing.At the same time, it has a certain independent research and development capability, and applies advanced technology to the design of electric heating products to create the best product value for customers.

The company is in strict accordance with the ISO9001 quality management system for manufacturing, all products are in line with CE and ROHS testing certification.

Our company has introduced advanced production equipment, precision testing instruments, the use of high-quality raw materials; Have a professional technical team, perfect after-sales service system; Design and manufacture various types of high quality heater products for injection molding machines, suction machines, wire drawing machines, blow molding machines, extruders, rubber and plastic equipment and other industries.