Exhaust gas treatment heater

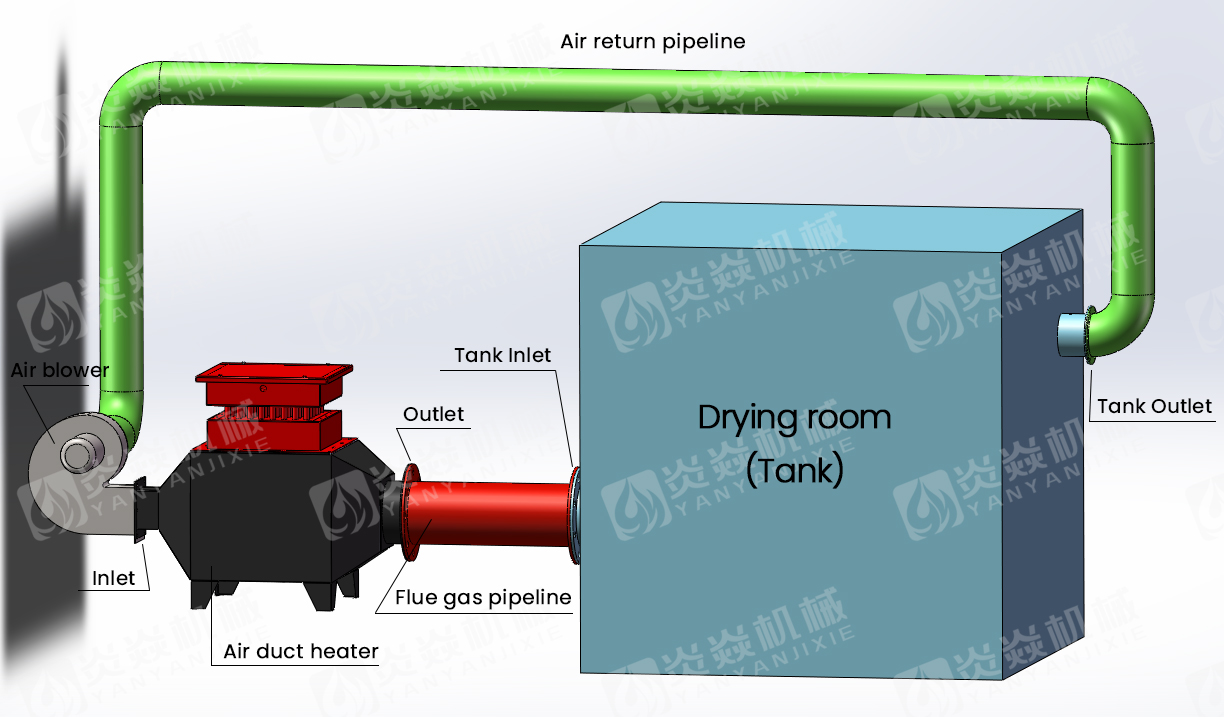

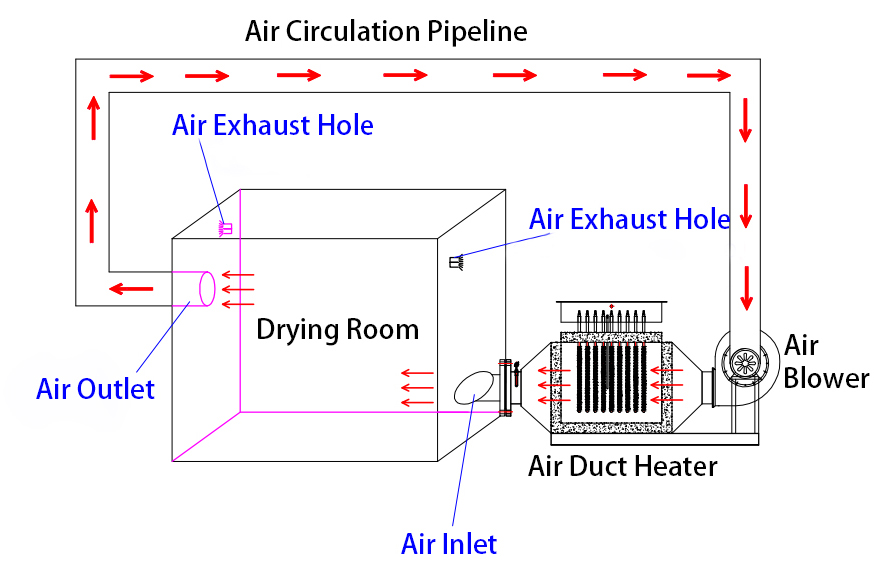

Working principle

Exhaust gas treatment heater is mainly used for air heating in the duct, specifications are divided into low temperature, medium temperature, high temperature three forms, the common place in the structure is the use of steel plate to support the electric pipe to reduce the vibration of the electric pipe, the junction box is equipped with overtemperature control device. In addition to the control of the overtemperature protection, but also installed between the fan and the heater, to ensure that the electric heater must be started after the fan, before and after the heater added a differential pressure device, in case of fan failure, the channel heater heating gas pressure generally should not exceed 0.3Kg/cm2, if you need to exceed the above pressure, please choose the circulating electric heater; Low temperature heater gas heating higher temperature does not exceed 160℃; Medium temperature type does not exceed 260℃; High temperature type does not exceed 500℃.

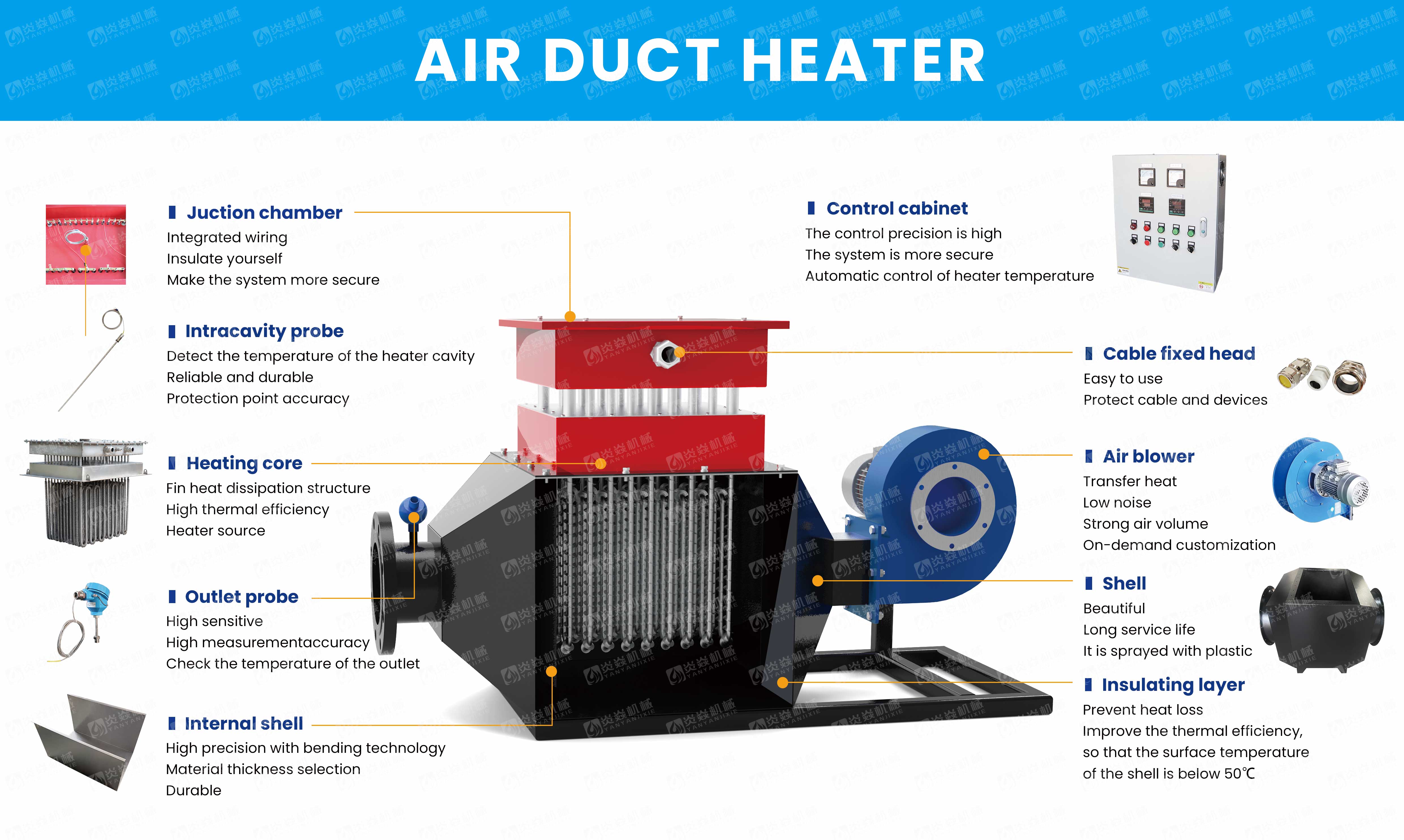

Product details display

Working condition application overview

Preheating: Through the action of hot air, desulfurization and denitration equipment can reach the working temperature faster, thereby improving the reaction speed and concentration, and improving the efficiency and effect of desulfurization and denitration.

Improve combustion adequacy: electric hot blast stove can effectively improve the adequacy of combustion, increase the temperature and pressure of combustion, so that pollutants can be better decomposed and removed in the combustion process, which is of great significance for improving environmental quality and protecting health.

Environmental protection and emission reduction: desulfurization and denitrification technology can effectively reduce the emission of atmospheric pollutants, such as sulfur dioxide and nitrogen oxides, thereby improving air quality and protecting the environment. Fast heating: The electric hot blast stove uses electric heating for air heating, which has fast heat transfer speed and fast heating speed, which greatly improves the production efficiency.

High efficiency and energy saving: electric hot blast stove uses efficient electric energy heating, which can improve the utilization rate of heat energy, reduce energy waste and reduce production costs.

Safe and reliable: the electric hot blast stove adopts a fully automatic control system, which can automatically adjust the temperature and intelligent temperature control, avoid the operator's operation error and ensure production safety.

Simple maintenance: electric hot blast stove has simple structure, easy operation, low maintenance cost and extended equipment life

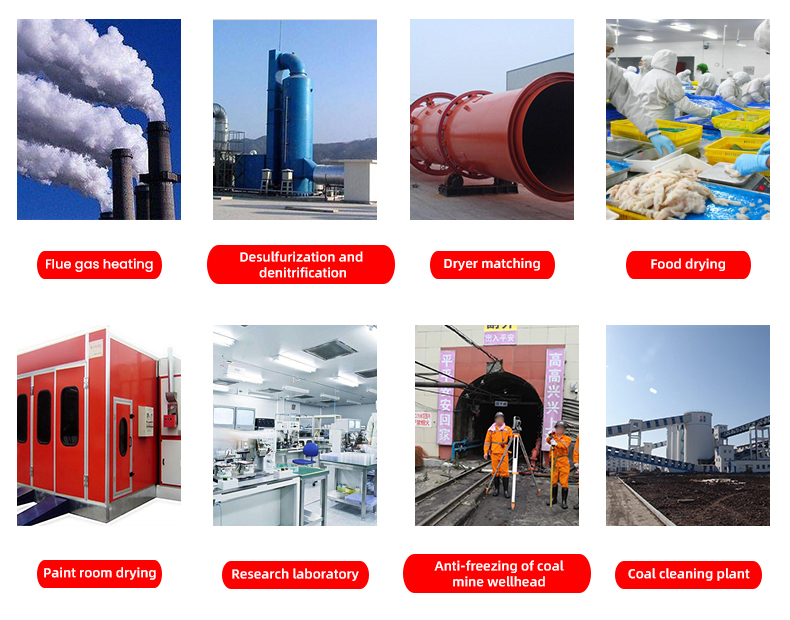

Application

Air duct electric heater is mainly used to heat the required air flow from the initial temperature to the required air temperature, up to 500 ° C. It has been widely used in aerospace, weapons industry, chemical industry and many scientific research and production laboratories in colleges and universities. It is especially suitable for automatic temperature control and high flow and high temperature combined system and accessory test. The electric air heater can be used in a wide range: it can heat any gas, and the generated hot air is dry and water-free, non-conductive, non-burning, non-explosive, non-chemical corrosion, pollution-free, safe and reliable, and the heated space is heated fast (controllable).

Customer use case

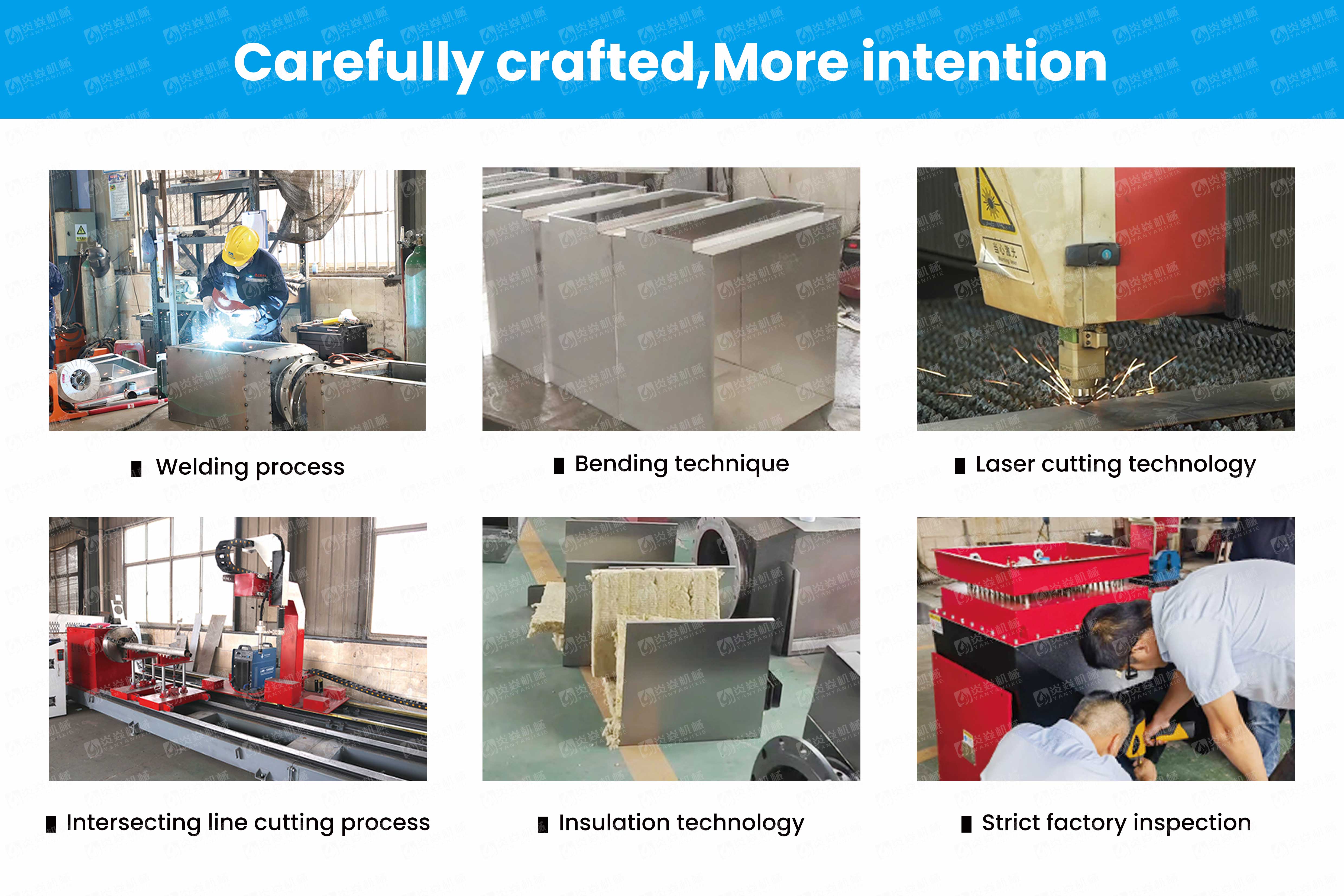

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services