Customized Pipeline Heater for Nitrogen Gas

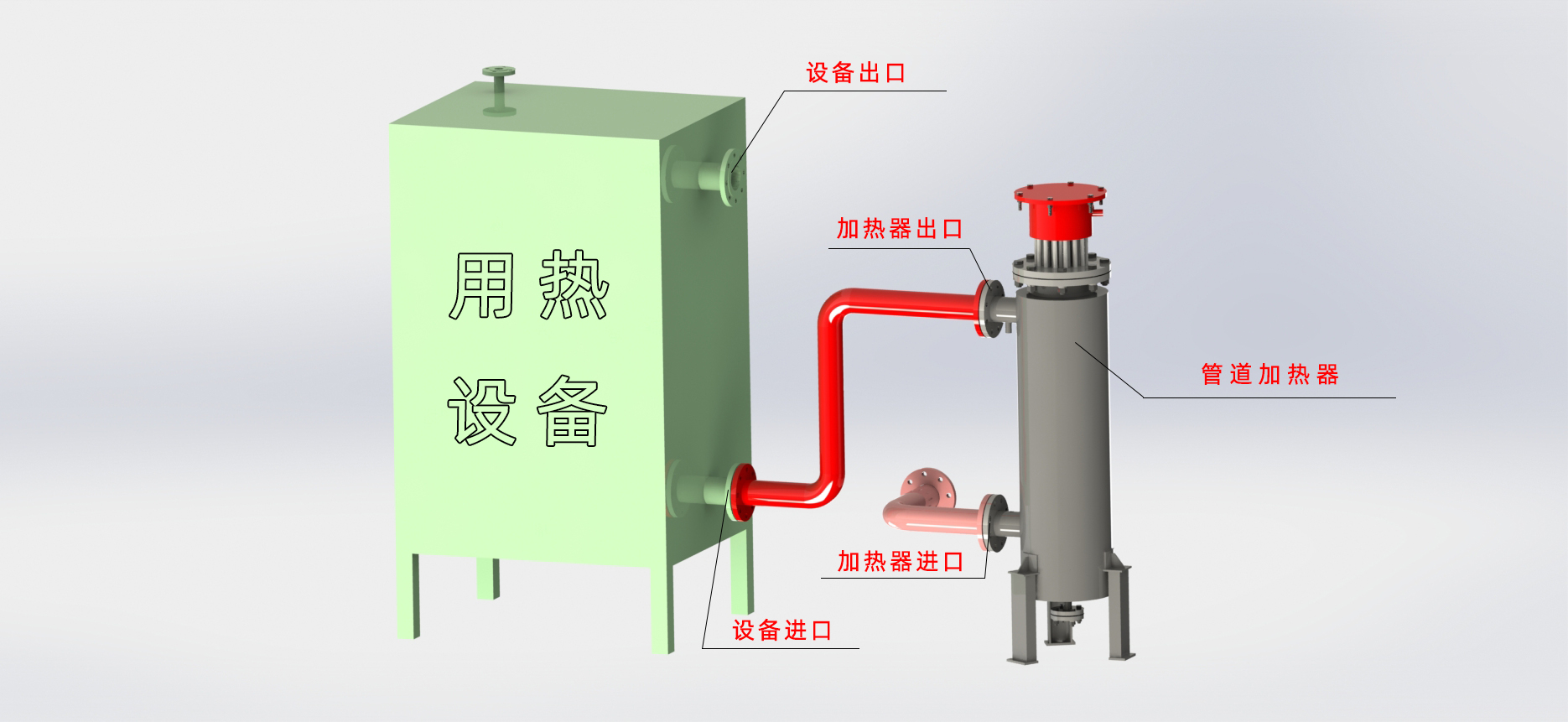

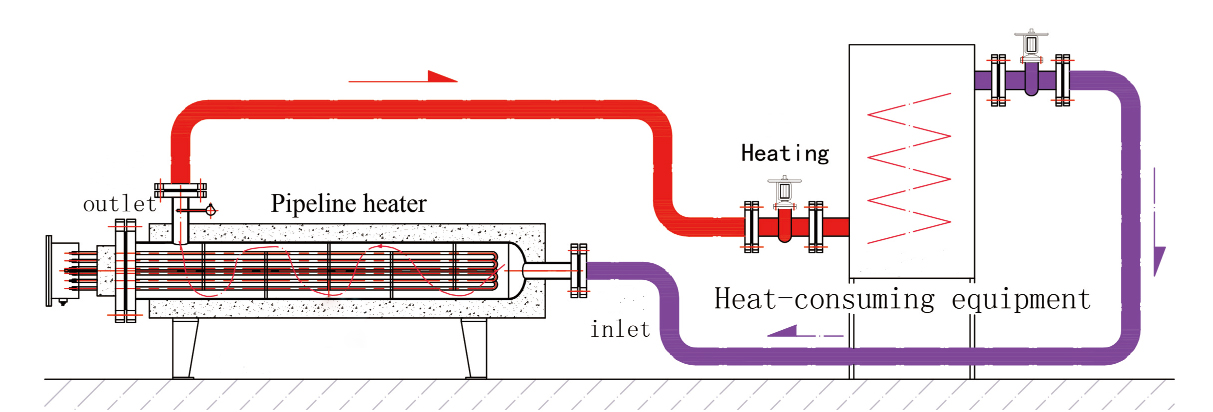

Working principle

Pipeline electric heater is a device that consumes electrical energy to convert it into thermal energy for heating materials that need to be. During operation, the low-temperature fluid medium enters its inlet under pressure, flows through the specific heat exchange channels inside the electric heating vessel, and follows path designed based on fluid thermodynamics principles, carrying away the high-temperature heat energy generated by the electric heating elements, thus increasing the temperature of the heated medium The outlet of the electric heater obtains the high-temperature medium required by the process. The internal control system of the electric heater automatically regulates the output power of the heater according to the temperature sensor signal at the outlet, maintaining a uniform temperature of the medium at the outlet; when the heating element overheats, the independent over protection device of the heating element immediately cuts off the heating power supply, preventing the heating material from overheating, causing coke, deterioration, and carbonization, and severe cases, causing the heating element to burn out, effectively extending the service life of the electric heater.

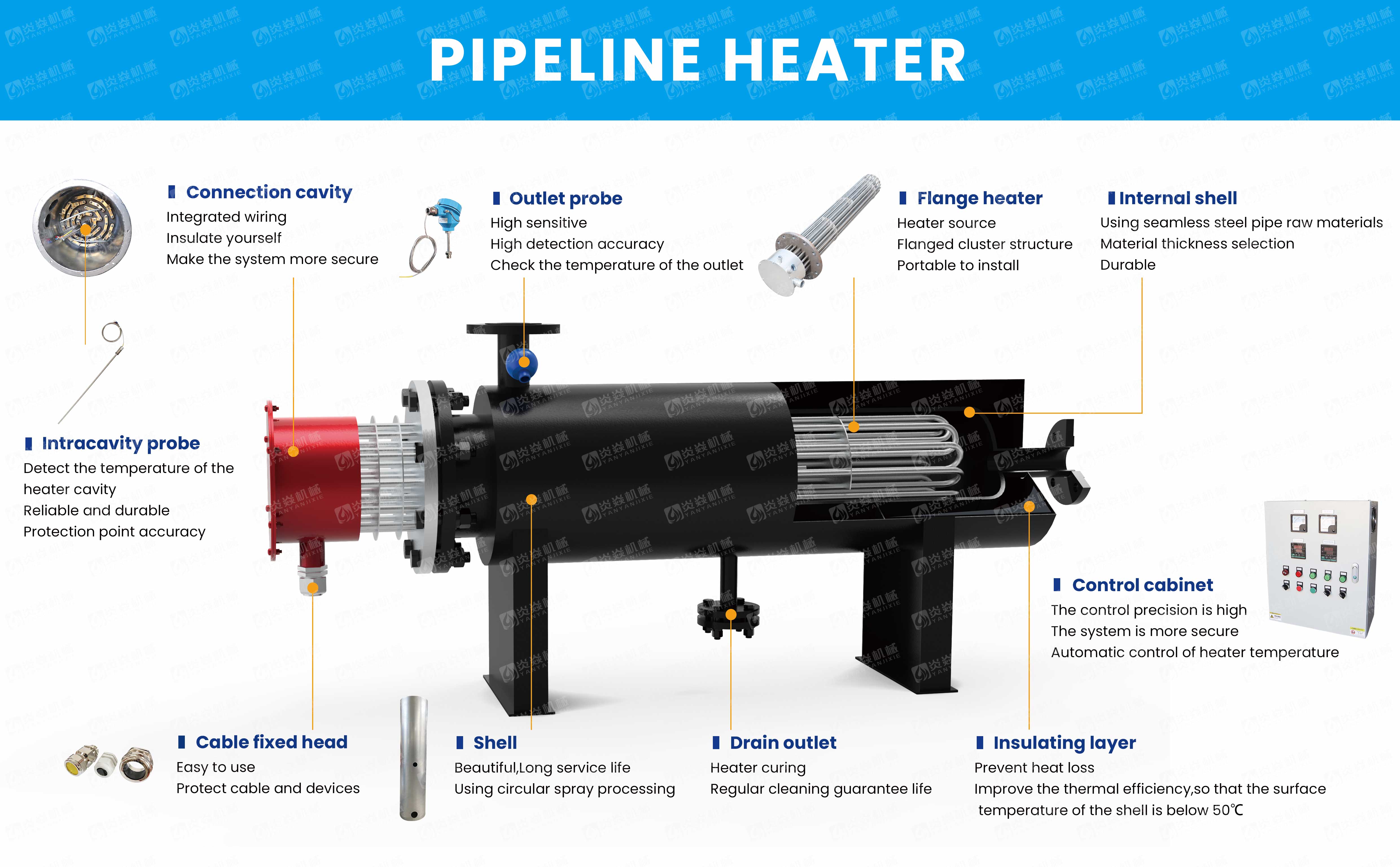

Product details display

The air circulation pipeline heater is a device used to heat air and transport it through a pipeline system to different spaces. It is commonly used in industrial heating or ventilation systems to ensure that the air maintains a suitable temperature during circulation.

Product feature

Fast heating speed: nitrogen can be heated to the required temperature in a short time.

Good thermal insulation performance: For example, the stainless steel pipeline nitrogen heater adopts a thickened insulation layer to reduce heat loss, maintain temperature stability, and save electricity.

High heating temperature: the medium can be heated from the initial temperature to the required temperature, up to 800℃.

High safety: the heating medium is non-conductive, non-combustible, non-explosive, non-chemically corrosive, and non-polluting; an overheating protector is configured to avoid damage to the heating elements and the system.

High thermal efficiency: the flow direction of the medium is reasonably designed, the heating is uniform, and there is no high or low temperature dead corner.

Strong adjustability: the control part adopts an advanced system, which can realize adjustable temperature measurement and constant temperature functions, and the user can also set the temperature freely.

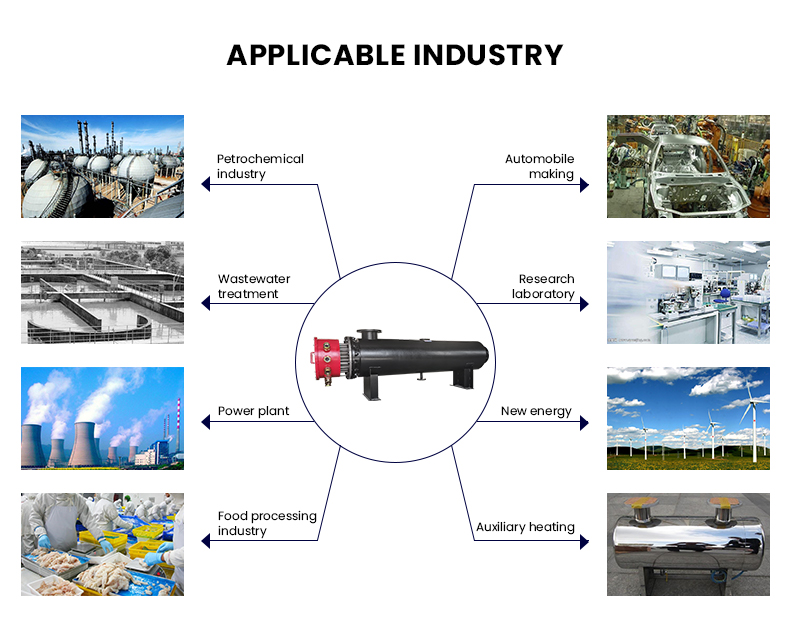

Product application

Pipeline nitrogen heaters are widely used in many scientific research and production laboratories such as aerospace, weapons industry, chemical industry, and colleges and universities. They are particularly suitable for automatic temperature control and large flow high temperature joint systems and accessory tests. In addition, it can also be used in chemical fiber industrial furnaces, drying rooms for heating and drying (such as cotton, medicinal materials, grain, etc.), hot air furnaces in paint rooms, and preheating of fuel oils such as heavy oil, asphalt, and clean oil.

Classification of heating medium

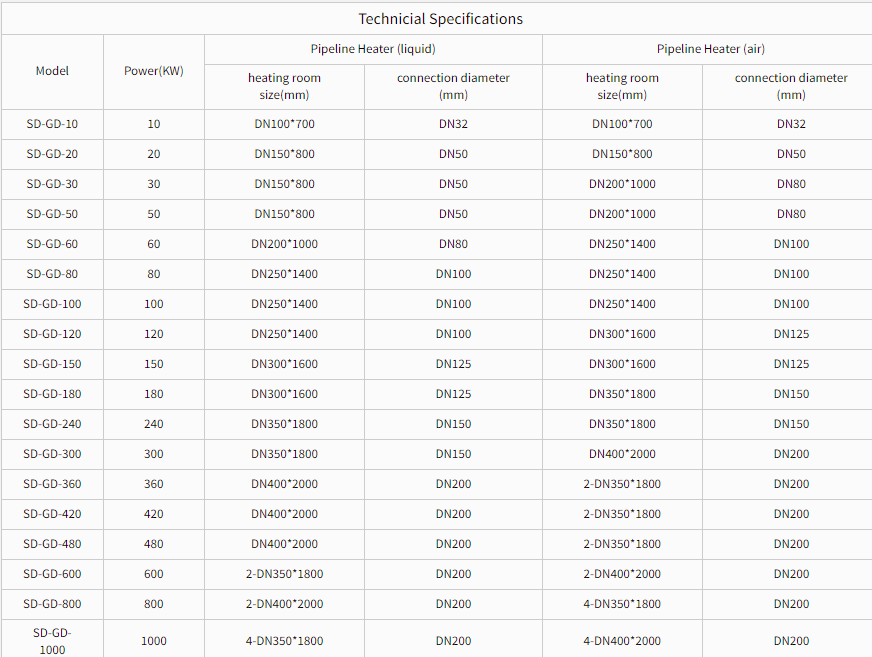

Technicial Specifications

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services