Chemical reactor pipeline heater

Working principle

Chemical reactor pipeline heater working principle is mainly based on the process of converting electrical energy into heat. Specifically, the electric heater contains an electric heating element, usually a high-temperature resistance wire, which heats up when the current passes through, and the resulting heat is transferred to the fluid medium, thus heating the fluid.

The electric heater is also equipped with a control system, including temperature sensors, digital temperature regulators and solid-state relays, which together form a measurement, regulation and control loop. The temperature sensor detects the temperature of the fluid outlet and transmits the signal to the digital temperature regulator, which adjusts the output of the solid state relay according to the set temperature value, and then controls the power of the electric heater to maintain the temperature stability of the fluid medium.

In addition, the electric heater may also be equipped with an overheat protection device to prevent the heating element from overtemperature, avoid medium deterioration or equipment damage due to high temperature, thereby improving safety and equipment life.

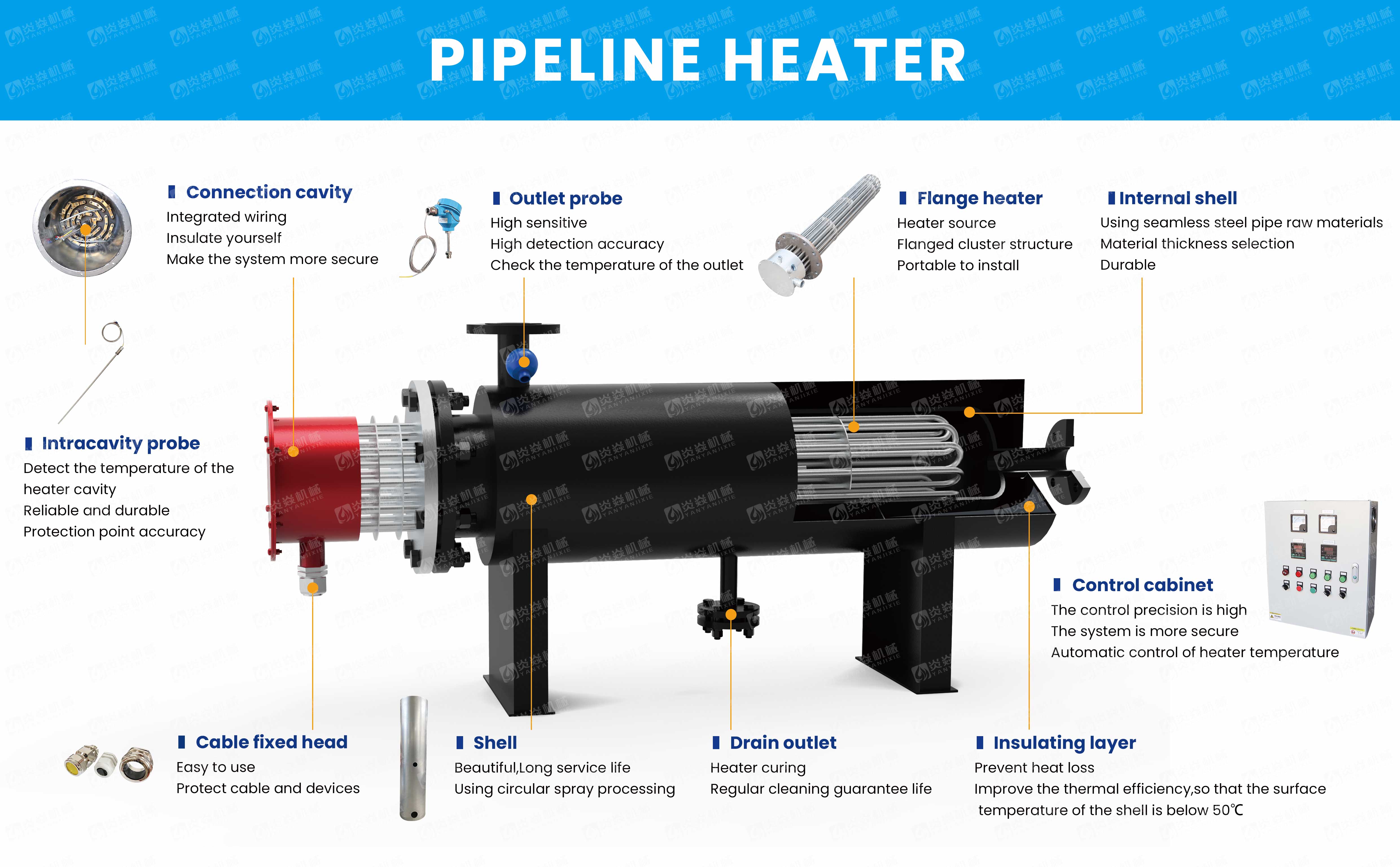

Product details display

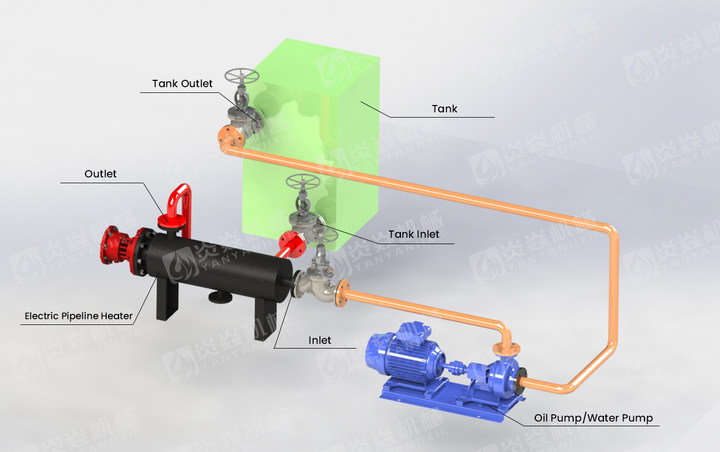

Working condition application overview

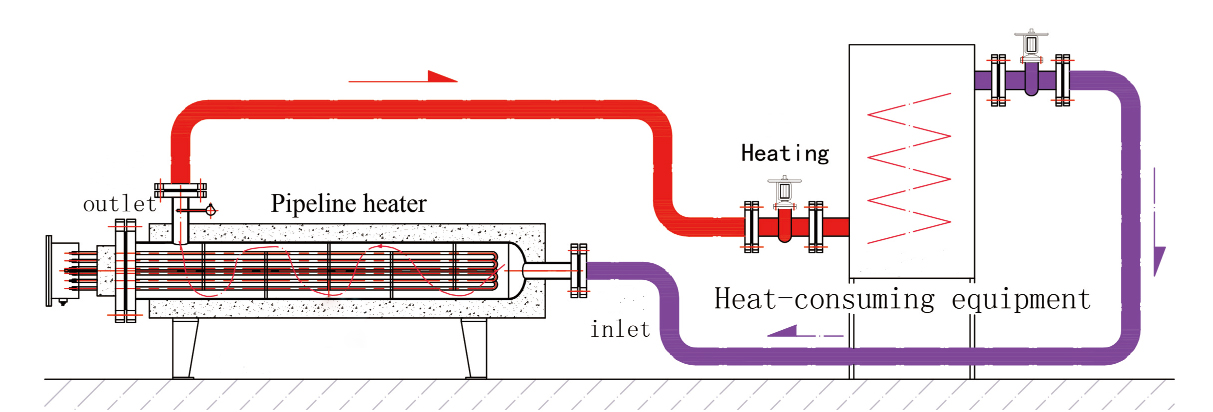

The working principle of the chemical pipeline preheating cycle electric heater is mainly based on the process of converting electrical energy into heat energy. Specifically, the electric heater contains an electric heating element, usually a high-temperature resistance wire, which heats up when the current passes through, and the resulting heat is transferred to the fluid medium, thus heating the fluid.

The electric heater is also equipped with a control system, including temperature sensors, digital temperature regulators and solid-state relays, which together form a measurement, regulation and control loop. The temperature sensor detects the temperature of the fluid outlet and transmits the signal to the digital temperature regulator, which adjusts the output of the solid state relay according to the set temperature value, and then controls the power of the electric heater to maintain the temperature stability of the fluid medium.

In addition, the electric heater may also be equipped with an overheat protection device to prevent the heating element from overtemperature, avoid medium deterioration or equipment damage due to high temperature, thereby improving safety and equipment life.

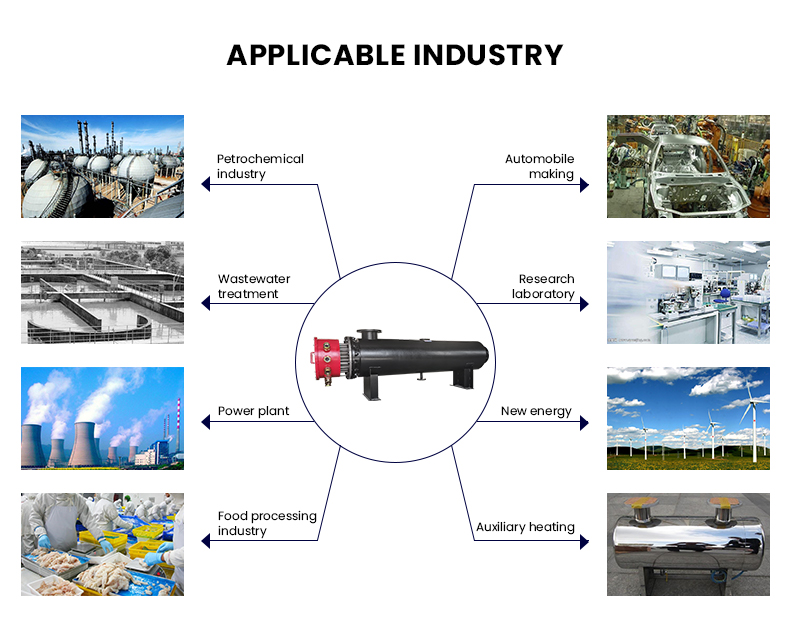

Product application

Pipeline heater widely used in aerospace, weapons industry, chemical industry and colleges and universities and many other scientific research and production laboratory. It is especially suitable for automatic temperature control and large flow high temperature combined system and accessory test, the heating medium of the product is non-conductive, non-burning, non-explosion, no chemical corrosion, no pollution, safe and reliable, and the heating space is fast (controllable).

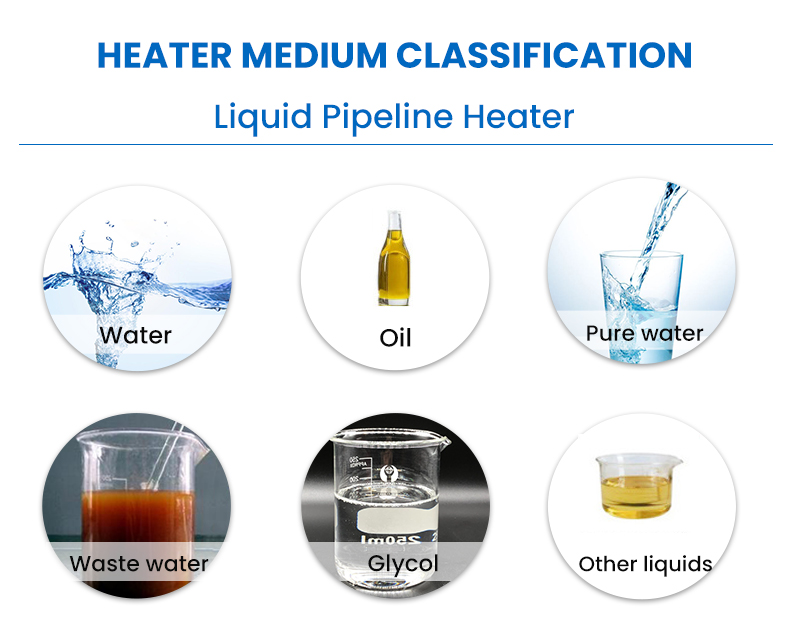

Classification of heating medium

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services