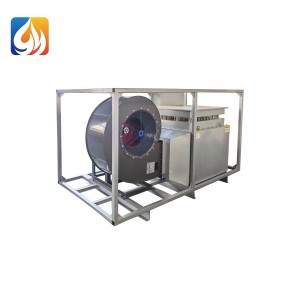

Air Duct Heater for Auxiliary Heating in Air Conditioning Systems

PROduct Introduction

The auxiliary electric heater of the air duct type (i.e., the auxiliary electric heater of the air duct type) automatically adjusts its own resistance according to the high and low temperature of the outlet air, so as to automatically compensate the heat, and has the characteristics of high heating coefficient, high safety, energy saving, and convenient installation. When the auxiliary electric heater works, the temperature on the surface of the electric heating tube will continue to rise. At this time, the air passes through the auxiliary electric heater, which reduces the temperature on the surface of the electric heating tube and simultaneously increases the temperature of the air. The heated air is then sent to the user end through the air duct. The power of the auxiliary electric heater can be divided into 2-6 groups to control, so as to meet different environments and heating needs. There is a temperature control sensor inside the auxiliary electric heater, which senses the temperature around it in real time. When the temperature exceeds the safe temperature, the temperature control sensor transmits a control signal, and the control circuit is designed to control the power supply of the auxiliary electric heater according to this characteristic.

Technical Date Sheet

.jpg)

Advantages

Improve the comfort of indoor temperature: Air duct conditioning auxiliary heating can be intelligently adjusted according to the indoor temperature conditions, maintaining a constant temperature and improving comfort. It can evenly distribute thermal energy, avoiding the local high temperature and temperature areas of traditional radiators, making the indoor temperature more balanced.

Energy saving: Air duct air conditioning auxiliary heating uses the principle of heat pump to fully utilize energy, greatly reducing energy consumption.

Smart control, automatic adjustment: The intelligent control system combines with the outdoor environment to automatically adjust the indoor temperature, making the no longer cold.

Suitable for a variety of scenarios: Air duct air conditioning auxiliary heating has a wide range of applications, including family, office, commercial buildings etc. In public places, the temperature is automatically adjusted according to the density of people flow, improving the service experience. In the family, it intelligently adjusts the temperature of rooms to meet the needs of different members.

Save installation costs and space occupation: There is no need to install additional equipment, and auxiliary heating can be achieved by the original air conditioning system. The auxiliary heating method reduces the use of traditional radiators and other equipment, reducing installation costs and space occupation.

Environmentally friendly and to use: Air duct air conditioning auxiliary heating does not produce dust and odors, keeping the indoor air clean.

Working condition application overview

Air duct frame type electric heater, mainly acting on the flow of air in the air duct heating, can be directly installed in the required heating environment of the pipe, the use of steel plate to support the electric heat pipe, air duct heater for industrial pipes, air conditioning pipes and various industrial air, by heating the air to increase the temperature of the output air. Usually inserted into the lateral opening of the air duct.

The inner cavity of the air duct electric heater is provided with a plurality of baffles (deflectors) to guide the gas flow direction and extend the retention time of the gas in the air duct, so that the gas is fully heated, the gas is heated evenly, and the heat exchange efficiency is improved. The heating element of the air duct electric heater is a stainless steel heating tube, which is filled with electric heating wire in the seamless steel pipe, and the void part is filled with magnesium oxide powder with good thermal conductivity and insulation. When the current passes through the high-temperature resistance wire, the heat generated is diffused to the surface of the heating tube through the crystalline magnesium oxide powder, and then transferred to the heated gas to achieve the purpose of heating.

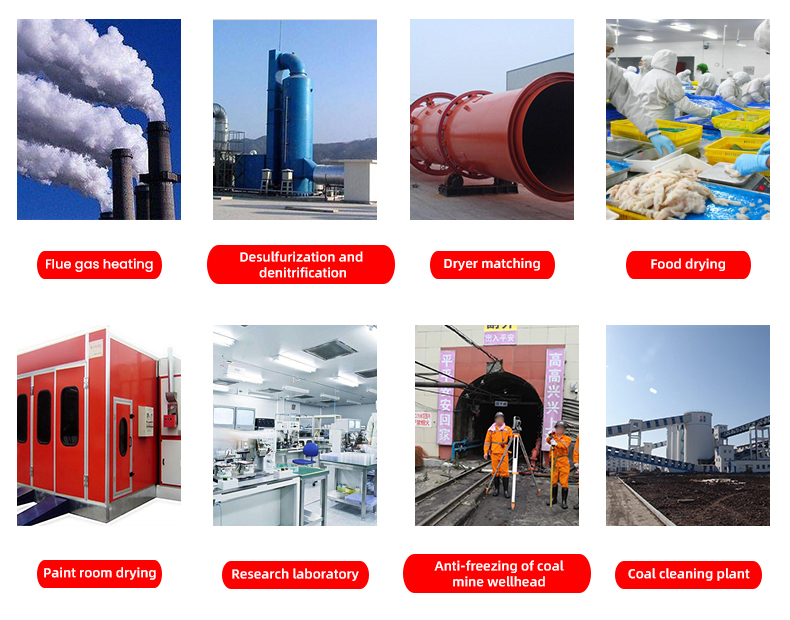

Application

Air duct electric heater is mainly used to heat the required air flow from the initial temperature to the required air temperature, up to 500 ° C. It has been widely used in aerospace, weapons industry, chemical industry and many scientific research and production laboratories in colleges and universities. It is especially suitable for automatic temperature control and high flow and high temperature combined system and accessory test. The electric air heater can be used in a wide range: it can heat any gas, and the generated hot air is dry and water-free, non-conductive, non-burning, non-explosive, non-chemical corrosion, pollution-free, safe and reliable, and the heated space is heated fast (controllable).

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services