245*60mm 650W Electric Far Infrared Ceramic element heater for thermoforming

Product Description

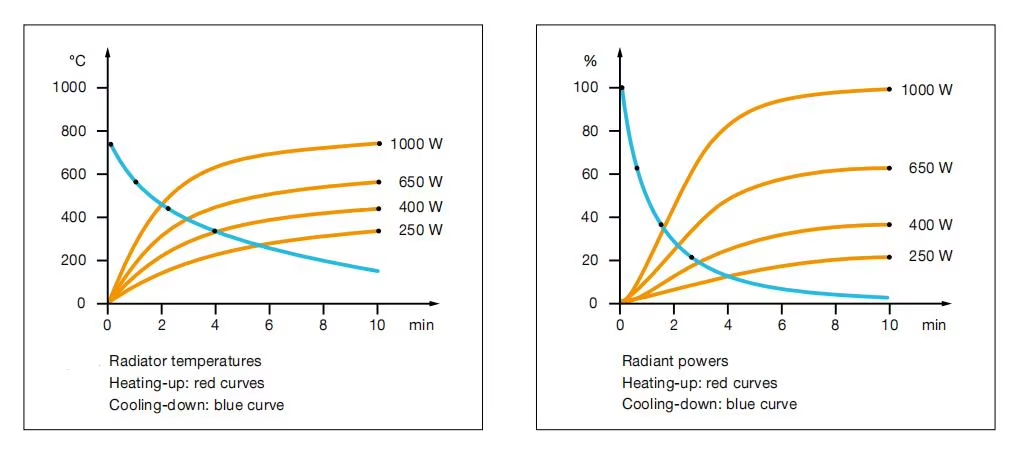

Ceramic infrared heater panel are working under temperature 300°C to 700°C (572°F - 1292°F) producing infrared wavelengths in the range of 2 to 10 micron, which is in the most suitable distance for plastics and many other materials absorb, which makes infrared ceramic heater the most efficient infrared radiant emitter on the market.

A range of aluminized steel reflectors are also available to ensure that most of the radiation generated is reflected forward on to the target area.

Advantage:

1. Energy-saving performance: The surface of the ceramic heating element is covered with small and dense holes, which makes it able to dissipate heat faster and more evenly, heat efficiency is higher, and it can heat up faster and save energy.

2. Long life performance: Ceramic material has good high temperature resistance, corrosion resistance, wear resistance and high strength performance, so that ceramic heating elements can run for a long time in high temperature environment, and will not be damaged because of thermal expansion and contraction.

3. Reliable high temperature performance: ceramic materials have stable performance at high temperatures and can withstand high temperature environments of up to 1000℃ or more, even if used at high temperatures for a long time, there will be no cracking, failure and other phenomena.

4. High safety: Due to the large thermal inertia of the ceramic material, it heats quickly and maintains stability, and has a certain heat insulation performance, making it able to effectively prevent the danger caused by electrical short circuit.

5. Good corrosion resistance: The corrosion resistance of ceramic materials is very good, and it can run for a long time in corrosive environments such as acid and alkali, and will not be corroded by them and cause failure.

6. Wide applicability: ceramic heater sets are widely used in drying, melting, heating, extractum, porcelain table decoration and some other industrial fields, and can also be used in household appliances and other fields, its adaptability is very good.

Application

1.PET perform heating in stretch blow molding machines

2.Printing Ink drying in offset machines

3.Screen-printing curing on T-shirts and textiles

4.Powder coating curing

5.Rubber coated drying

6.Sterilizing/mirror coating drying in glass industries

7.Paint baking

8.Paper coating drying

9.All type of lamination

Preheating prior to embossing

Certificate and qualification

Team

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services